Coconut (cocos nucifera) is one of the world most useful and important perennial plants. A coconut fruit is made up of an outer exocarp, a thick fibrous fruit coat known as husk, underneath is the hard protective endocarp or shell, the edible endosperm and the milk.

Everything in between the shell and the outer coating or exocarp of the coconut seed is considered coco coir.

Coco coir, also known as coconut fiber, is a natural, renewable material derived from the husks of coconuts. The fibres are extracted from the outer husk of coconut, which are fibrous material found between the hard, internal shell and the outer coat of the coconut.

The coconut coir was initially considered a waste byproduct of coconut farming. In the past, coconuts were only grown for their edible interior pulp and the use of the husk for fire making. However, people came to realize the husks on the outside of coconuts are also quite useful.

Soil, a grow media was then the only medium on which people recognize for growing crops. Unfortunately, the imperfection of soils, a reason why farmers add soil amendments to improve their soils and make it a growing place for plants, still does not make soil a media for soilless farming. As new technology was developed such as soilless farming coco coir came to being as a new media for growing crops. Today, growing media such as coco coir are used in place of soil and peat moss. This substrate gives plants a supportive medium within which to grow and expand their roots. In their rawest form, soilless substrates like coconut coir do not contain any nutrients, so they are considered “inert.” However, coco coir is sometimes mixed with amendments like bat guano and other types of fertilizers to make blends and increase the nutrient status of the coir.

In Hydroponic farming, growers are drawn to raw, inert coco coir because it gives them precision control over their watering schedules.

To be successful in hydro growing, the growers must create nutrient mixes within very specific ranges of pH, PPM, and EC. To do so, they must use inert substrates which do not cause fluctuations in pH reading.

Coconut coir has a pH reading of 7, therefore, considered “ neutral.” As such, using raw coco coir as a hydroponic substrate will not influence the pH of irrigation water. For this reason, coco coir is the ideal substrate to use for hydroponics farming.

WORLD PRODUCERS OF COCONUT COIR

Major producers of Coir in the world as at year 2020 include [Country Weight (tonnes)]:

India -586,686, Vietnam- 390,541, Sri Lanka -161,791,

Thailand- 64,098, Ghana- 39,548, and all others – 33,960.

Total world coir fibre production is 1,276,624 tonnes (1,256,462 long tons; 1,407,237 short tons), with India( mainly in the coastal region of Kerala State), producing 60% of the total world supply of white coir fibre. Sri Lanka produces 36% of the total brown fibre output. Over 50% of the coir fibre produced annually throughout the world is consumed in the countries of origin, mainly India. Together, India and Sri Lanka produced 59% of the coir produced in 2020. Sri Lanka remains the world’s largest exporter of coir fibre and coir fibre based products.

HISTORY OF COCONUT COIR

Sennit, a type of cordage made by plaiting strands of dried fibre or grass can be used ornamentally in crafts, like a kind of macramé, or to make straw hats. Sennit is an important material in the cultures of Oceania, where it is used in traditional architecture, boat building, fishing and as an ornamentation. It is made from plaited coconut fibre on a traditional house in Fiji

The name coir comes from கயிறு (kayiru), കയർ (kayar), the Tamil in india and Malayalam words respectively for cord or rope (traditionally, a kind of rope made from the coconut fibre). Ropes and cordage have been made from coconut fibre since ancient times. The Austronesian peoples, who first domesticated coconuts, used coconut fibre extensively for ropes and sennit in building houses and lashed-lug plank boats in their voyages in both the Pacific and the Indian Oceans.

Later Indian and Arab navigators who sailed the seas to Malaya, China, and the Persian Gulf centuries ago also used coir for their ship ropes. Arab writers of the 11th century AD referred to the extensive use of coir for ship ropes and rigging.

A coir industry in the UK was recorded before the second half of the 19th century. During 1840, Captain Widely, in co-operation with Captain Logan and Thomas Treloar, founded the known carpet firms of Treloar and Sons in Ludgate Hill, England, for the manufacture of coir into various fabrics suitable for floor coverings.

PRODUCTION OF COCO COIR

The coconut fruit is made up of different layers. The coir lies between outer exocarp to the inner shell. To produce the coco coir, the fibrous layer of the fruit is separated from the hard shell (manually) by driving the fruit down onto a spike to split it (dehusking). A well-seasoned husker can manually separate 2,000 coconuts per day. Machines can also be used to crush the whole fruit to give the loose fibres. These machines can process up to 2,000 coconuts per hour.

After removal of the shell and the endosperm, the multipled layered coconut husk fiber are placed on a stone ground, soaked then dried for over a year.

To get coconut coir ready for hydroponic and gardening uses, it must undergo extensive processing as follows:.

Firstly, the coir is remove from the coconuts by soaking the husks in water to loosen and soften them. This is either done in tidal waters or freshwater. If done in tidal waters, the coconut coir will take up a large amount of salt, which will need to be flushed out by the manufacturer at a later stage.

Then, they are removed from the water bath and dried for over a year. After the drying process, which is quite extensive, the coir is organized into bales. These bales are then chopped and processed into various formats, from chips, to “croutons”, to classic ground coconut coir.

In 2009, researchers at CSIR’s National Institute for Interdisciplinary Science and Technology in Thiruvananthapuram developed a biological process for the extraction of coir fibre from coconut husk without polluting the environment. The technology uses enzymes to separate the fibres by converting and solubilizing plant compounds to curb the pollution of waters caused by retting of husks.

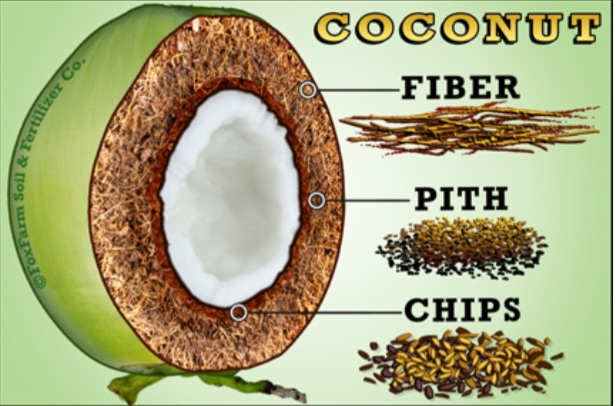

PARTS OF THE COCONUT HUSK THAT FORM THE COIR

Coco coir is made from a few different parts of the coconut husk. The three primary parts of the coconut husk are the pith, fiber, and chips. These materials are used in a variety of consumer products such as soil amendments, top dressings, floor mats, rope, brushes and fishing nets.

THE PITH: The pith of the coconut husk comprises of extremely fine material. Coconut pith is responsible for the water retention abilities of coco coir.

Note: coconut pith is not used as a stand-alone cultivation medium because it does not drain well.

THE FIBER: Coconut fiber is the long, stringlike material that encompasses coconut husks. This fiber is extremely strong, yet it does not absorb water. As such, coconut fiber is responsible for giving coco coir its aeration qualities.

THE CHIPS: Coconut chips are exactly what they sound like – chunks of coconut husks that resemble wood chips.

PROPERTIES OF COCO COIR

1. Coco coir is a natural, eco-friendly alternative to traditional grow media.

2. It has a natural pH of around 5.5 to 6.8.

3. It promotes healthy root development.

4. It supports beneficial microbe additives.

5. It is used in products such as floor mats, doormats, brushes, and mattresses.

6. There are two varieties of coir, the white and brown coir. The brown coir (made from ripe coconut) are used in upholstery padding, sacking and horticulture.

7. White coir, harvested from unripe coconuts, is used for making finer brushes, string, rope and fishing nets.

8. It has the advantage of not sinking, so can be used in long lengths in deep water without the added weight dragging down boats and buoys.

9. Coco peat has high cellulose and lignin content.

10. Coco peat which differ from coco coir is acidic with pH range of 5.5 to 6.5, which is slightly too acidic for some plants, but many popular plants can tolerate this pH range.

11. Coconut fiber (CF) has low thermal conductivity, is very tough, ductile, durable, renewable and inexpensive.

12. It was observed in an experimental study that by partially replacing 2% of cement with CF, the compressive strength of the concrete is increased.

STRUCTURE OF COCONUT COIR (FORMS IN WHICH COIR COIR FIBRE CAN APPEAR)

Coir fibres are found between the hard, internal shell and the outer coat of a coconut. The individual fibre cells are narrow and hollow, with thick walls made of cellulose. They are pale when immature, but later become hardened and yellowed as a layer of lignin is deposited on their walls.

Each cell that make up a fiber is about 1 mm (0.04 in) long and 10 to 20 μm (0.0004 to 0.0008 in) in diameter. Fibres are typically 10 to 30 centimetres (4 to 12 in) long.

The coir fibre can be Segregated into:

a. COIR

Coir must not be confused with coir pith, which is the powdery and spongy material resulting from the processing of the coir fibre.

b. COIR FIBRE

Coir fibre is locally named ‘coprah’ in some countries, adding to confusion.

c. PITH

Pith is chemically similar to coir, but contains much shorter fibers.

d. COCO PEAT

The name coco peat may refer either to coir or the pith or a mixture, as both have good water-retaining properties as a substitute for peat.

TYPES OF COCO COIR

Purchased coconut coir product has a combination of its three types of the coconut coir: the fiber, the pith (or coconut peat), or the coco chips. This product is a wonderful growing medium with specific benefits.

1. COCO PITH OR COCO PEAT: It is so called “coco peat” because it is the fresh coco fibre somewhat like what peat is to peat moss, although it is not true peat. It is made of finely ground coconut or peat moss.

The “peat” of coconut coir, pith looks like finely ground coconut or peat moss. It is so small and absorbent that if it is solely used as growing medium might result in drowning out the roots from the plants.

It needs proper ageing before use as it can let out salts that will kill the plant if care is not taken. It is usually shipped in the form of compressed bales, briquettes, slabs or discs, the end user usually expands and aerates the compressed coco peat by the addition of water. A single kilogramme of dry coco peat will expand to 15 litres of moist coco peat.

When coco peat is not fully decomposed especially those shipped on arrival, they will use up the available nitrogen in them. As it does so (known as drawdown), it competes with the plant if there is not enough nitrogen in it. This is called nitrogen robbery. It can cause nitrogen deficiency in the plants. Poorly sourced coco fibre can have excess salts in it and needs washing. It holds water well and holds around 1,000 times more air than soil.

2. COCO FIBER: The fiber can improve airflow but it is not very absorbent. Coconut fiber adds air pockets into the medium. It’s not very absorbent, which is good because the growing media needs air pockets in order to provide oxygen to the root zone. Coconut fibers do break down rather quickly, meaning the air pockets they create will also decrease over time. In addition, adding slow release fertilizers or organic fertilizers are highly advised when growing with coco fibre.

3. COCO CHIPS: This is a hybrid between coconut peat and coconut fiber. Coconut chips are basically a natural type of expanded clay pellet. They are made from plant matter instead of clay and are best thought of as a hybrid between coco peat and coco fiber. They are large enough to create air pockets but also absorb water, making plants not to dehydrate completely.

3. BRISTLE COIR

Bristle coir is the longest variety of coir fibre. It is manufactured from retted coconut husks through a process called defibering. The coir fibre thus extracted is then combed using steel combs to make the fibre clean and to remove short fibres. Bristle coir fibre is used as bristles in brushes for domestic and industrial applications.

When using coconut coir in the garden as growing medium, these three types ( coco chips, fiber and peat ), must be in the right mixture as a single product for best results.

VARIETIES OF COIR

There are two varieties of fibers that make up coir

Brown and white.

BROWN COIR

Brown coir harvested from fully ripened coconuts is thick, strong and has high abrasion resistance. It is typically used in mats, brushes and sacking. Mature brown coir fibres contain more lignin and less cellulose than fibres from flax and cotton. They are stronger but less flexible.

Brown coir is produced when fibrous husks are soaked in pits or in nets in a slow-moving body of water to swell and soften the fibres. The long bristle fibres are separated from the shorter mattress fibres underneath the skin of the nut, a process known as wet-milling.

The mattress fibres are sifted to remove dirt and other rubbish, dried in the sun and packed into bales. Some mattress fibre is allowed to retain more moisture so it retains its elasticity for twisted fibre production. The coir fibre is elastic enough to twist without breaking and it holds a curl as though permanently waved. Twisting is done by simply making a rope of the hank of fibre and twisting it using a machine or by hand.

The longer bristle fibre is then washed in clean water and then dried before being tied into bundles or hanks. It may then be cleaned and ‘hackled’ by steel combs to straighten the fibres and remove any shorter fibre pieces. Coir bristle fibre can also be bleached and dyed to obtain hanks of different colours.

WHITE COIR

White coir fibres are harvested from coconuts before they are ripe. They are white or light brown in colour and are smoother and finer, but also weaker. They are far more flexible but much less strong. They are generally spun to make yarn used in mats or rope.

The coir fibre is relatively waterproof, and is one of the few natural fibres resistant to damage by saltwater. Fresh water is used to process brown coir, while seawater and fresh water are both used in the production of white coir.

Almost all of the coconut coir used for hydroponics is brown coir, as it is processed even more after initial harvesting.

To produce white coir, the immature husks are suspended in a river or water-filled pit for up to ten months. During this time, micro-organisms break down the plant tissues surrounding the fibres to loosen them ( a process known as retting). The segments of the husk are then beaten with iron rods to separate out the long fibres which are subsequently dried and cleaned. Cleaned fibre is ready for spinning into yarn using a simple one-handed system or a spinning wheel.

SIGNIFICANCE OF COCO COIR

1. It is used in gardening, as a bedding material for pets, and in manufacturing.

2. Coco coir is a growing medium that can be used in potting mixes, soil amendments, and hydroponic systems.

3. It helps soil retain moisture and improves aeration.

4. Pet bedding: Coco coir can be used in worm bins, vivarium substrates, and as a natural bed for pets.

5. Manufacturing: Coco coir is used in the production of floor mats, doormats, brushes, and mattresses.

6. It is used in Cordage, packaging, bedding, flooring, and others

7. It is used for making coir rope especially in Kerala, India. The coir rope is used for connecting all parts of an outrigger canoe used at Sonsorol and Palau.

8. A small amount is also made into twine.

9. Pads of curled brown coir fibre, made by needle-felting (a machine technique that mats the fibres together), are shaped and cut to fill mattresses and for use in erosion control on river banks and hillsides.

10. A major proportion of brown coir pads are sprayed with rubber latex which bonds the fibres together (rubberised coir) to be used as upholstery padding for the automobile industry in Europe. The material is also used for packaging.

11. White coir is used for making fishing nets due to its strong resistance to saltwater.

12. In agriculture and horticulture, coir is used as an organic and decorative component in soil and potting mixes.

13. Coco coir has being an alternative to the use of other grow media. There has being an increasing concern regarding the sustainability of producing sphagnum (peat moss) and peat from peatlands, therefore, usage of alternative substrates like coco coir has been a substitute.

14. Coir is used to deter snails from delicate plantings, and also it is used as growing medium in intensive glasshouse (greenhouse) horticulture.

15. Coir is used in some hydroponic growing systems as an inert substrate medium.

It is also used as a substrate to grow mushrooms.

16. Coir can be used as a terrarium substrate for reptiles or arachnids.

17. Coir fibre pith or coir dust can hold large quantities of water, just like a sponge. It is used as a replacement for traditional peat in soil mixtures, or, as a soil-less substrate for plant cultivation.

18. Coir waste from coir fibre industries is washed, heat-treated, screened and graded before being processed into coco peat products of various granularity and denseness, which are then used for horticultural and agricultural applications and as industrial absorbent.

19. Coco peat is used as a soil conditioner. Due to low levels of nutrients in its composition, coco peat is usually not the sole component in the medium used to grow plants. When plants are grown exclusively in coco peat, it is important to add nutrients according to the specific plants’ needs. Coco peat from Philippines, Sri Lanka and India contains several macro- and micro-plant nutrients, including substantial quantities of potassium. This extra potassium can interfere with magnesium availability. Adding extra magnesium through the addition of magnesium sulphates can correct this issue.

20. Aeration and Water Retention: Aeration and water retention are some of the most impressive qualities of coco coir. By combining these important characteristics, coco coir has taken the hydroponics industry by storm.

When used in a hydroponics setup, there is no need to about substrate drying out between cycles.

21. Coco coir balances water absorption capabilities with amazing breathability. Coco coir allows air to penetrate deep into the root zone of plants. In turn, this breathability helps reduce the chance for diseases like root rot, while also supporting overall plant growth.

22. By mixing coco coir with amendments like earthworm castings, nutrients are added to the otherwise raw, inert substrate. The idea behind coco coir mixes is to keep the water retention and aeration qualities of the substrate, while complementing it with ingredients found in soil.

23. It can be used on its own or in a blend and it is a highly significant growing media. Hydroponic growers love coco coir because it gives them precision control over important factors like pH, PPM, and EC.

24. coconut coir can be used as a substitute for peat because it is free of bacteria and most fungal spores, and is sustainably produced without the environmental damage caused by peat mining.

25. Coco coir can be mixed with sand, compost and fertilizer to make good quality potting soil.

26. Coco coir has a high superior absorption capabilities compared to other products made of clay, silica and diatomaceous earth-based absorbents. Dry coconut coir pith is an oil and fluid absorbent. For example, In the 2024 Manila Bay oil spill, the DILG Bataan appealed for hay, hair and coconut coir pith (husk) to process into oil booms as absorbent for the Philippine Coast Guard’s cleanup operations.

27. Animal bedding: Coconut coir pith is also used as a bedding in litter boxes, animal farms and pet houses to absorb animal waste.

28. Coconut coir is biodegradable. Home growers and commercial producers alike can use large amounts of coco coir without concern for how to dispose it after use. It can be composted after use or even burnt.

29. Biocontrol: Trichoderma coir pith cake (TCPC), when prepared has successfully being used for control of plant diseases. The dry product TCPC has a long shelf life.

30. Coir can contain beneficial life-forms. Coconut coir from Mexico has been found to contain large numbers of colonies of the beneficial fungus Aspergillus terreus, which acts as a biological control against plant pathogenic fungi.

Trichoderma is a naturally occurring fungus in coco peat; it works in symbiosis with plant roots to protect them from pathogenic fungi such as Pythium.

31. Coir fiber is rarely used as a potting material, except for orchids, and does not need buffering. It has a very low cation-exchange capacity (CEC) capacity, hence not retaining salts.

PRECAUTIONS WHEN USING COIR

Coco fibre can be re-used up to three times with little loss of yield. Coco fibre from diseased plants should not be re-used unless sterilization is thoroughly done. Many sources of coir however are heavily contaminated with pathogenic fungi. Other risks associated with using coco coir include: high salt content, nutrient deficiencies (particularly calcium and magnesium), improper processing leading to inconsistent quality, and the need for careful pH management etc, all of which can negatively impact plant growth if not properly addressed by rinsing, buffering, and using appropriate nutrient solutions. This makes the choice of the source to be important.

The following safety guide should be known before using or purchasing coco coir:

1. Coir is an allergen, as well as the latex and other materials used frequently in the treatment of coir. Coconut coir is generally hypoallergenic and safe for people with allergies or sensitivities. It contains allergens such as Coc n 1, Coc n 2, and Coc n 4 proteins. Also, coconut-derived products like cocamide sulfate, cocamide DEA, and CDEA can cause contact dermatitis. Some of the

symptoms of a coconut allergy include hives, itching, nausea, skin rash, dizziness, coughing, diarrhea, sneezing, and swelling in the throat.

2. BIOSECURITY RISKS: Coco fibre can harbor organisms that pose a threat to the biosecurity of countries into which it is imported. For example, coco peat has been imported into New Zealand since about 1989 with a marked increase since 2004. By 2009 a total of 25 new weed species have been found in imported coco peat. The regulations relating to importing coco peat into New Zealand have been amended to improve the biosecurity measures.

3. SALT BUILD-UP: Unwashed coco coir can contain high levels of natural salts, which can harm plant roots if not properly leached out before use.

4. PATHOGEN CONTAMINATION:

Coco coir can potentially harbor harmful bacteria and fungi if not sourced from a reputable supplier and properly processed.

5. NUTRIENT IMBALANCES:

Coco coir naturally binds certain nutrients like calcium and magnesium, making it necessary to supplement with these elements when growing in this medium.

6. QUALITY INCONSISTENCY:

Different batches of coco coir can vary in quality, including salt levels and fiber structure, which can affect plant growth.

7. pH FLUCTUATIONS: Coco coir can be prone to pH changes, requiring careful monitoring and adjustment with appropriate buffers.

8. ENVIRONMENTAL CONCERNS: Water used for cleaning coco piths may contain high level of sodium, potassium, and physical contaminants that can have a harmful affect on surface water, groundwater, and soil. Also, as a renewable resource, the production of coco coir can sometimes involve unsustainable practices like water pollution and labor exploitation.

TREATMENTS AND STERILIZATION OF COCO COIR

Coco coir can be sterilized using heat, hydrogen peroxide, or quaternary ammonium salts. Sterilization is important to kill pathogens and weed seeds that can harm plant growth.

1. Coco peat may be sterilized to remove potential pathogens and weeds along with beneficial life. This may be done to remove contaminants in fresh material or to reuse old coir. Both heat (boiling or baking) and chemical means can be used.

Also, coir can becomes infected by patogens after storage. After the coir is separated from the coconuts, and stored in piles for few years, The coir will be at risk of pathogens infestion due to the natural pH of the coco coir. Most producers that experience this will chemically sterilize the coir so it’s ready for use. This also has its risks, as it can prematurely break down the fibers and peat.

Therefore, the following precautions should be adhered to:

a. Avoid situations that are conducive to pathogen growth

b .Have a dedicated system to control how the coconut coir ages

c. Rinse and wash the coir to flush out salts

d. Create the right blend of pith, fibers, and chips

e. Package and store their product correctly

2. Coir can also be pasteurised with boiling water. Coir mixed with vermiculite should be pasteurised with boiling water to kill pathogens and weed seeds especially in cases where the growing medium is to be used for mushroom production. After the coir/vermiculite mix has cooled to room temperature, it should be placed in a larger container. If the media is for mushroom production for example, spawn jars should be prepared, using substrates such as rye grains or wild bird seed, added to the media.

3. CALCIUM BUFFERING SOLUTION TREATMENT:

Because coir pith is high in sodium and potassium, it is treated before use as a growth medium for plants or fungi by soaking in a calcium buffering solution. Most coir sold for growing purposes is said to be pre-treated. Once any remaining salts have been leached out of the coir pith, it and the cocochips become suitable substrates for cultivating fungi. Coir is naturally rich in potassium, which can lead to magnesium and calcium deficiencies in soilless horticultural media.

LIMITATION OF COCO COIR

1. Coconut coir is inert, meaning it has no nutrients. Eventhough it looks like soil, it still lack nutrient. It can be used as a soil amendment but not alone as hydroponic growth substrate. There is need to add nutrients to it and control the pH when using as a grow media.

2. It needs rehydration. It is usually produced dry and shipped in dry condition. To rehydrate it, more work, labourers etc are required before use.

3. Mixes can be expensive. Coconut fiber soil mixes are expensive and annoying to work with compared to coconut coir mixes. This saves a lot of time but is pretty expensive.

HOW TO USE

To use coco coir, soak the brick in water and watch it expand. Once the entire brick has crumbled, the coir is ready to use.

STORAGE

Store coco coir in a cool, dry place and avoid exposing it to moisture or direct sunlight.