Recycling of waste materials is now gaining a lot of ground globally. Lots of waste materials are now produced during human activities, animal wastes and crop residues which are recycled into new valuable materials. This valuable products are rich carbonaceous products that are utilized in agricultural production.

Carbonaceous materials are any organic material that contains a large amount of carbon content. Examples include coal, hydrocarbon petroleum products (e.g., crude oil, natural gas), carbonaceous gases, biochar and some metals such as carbon steel and carbon alloys.

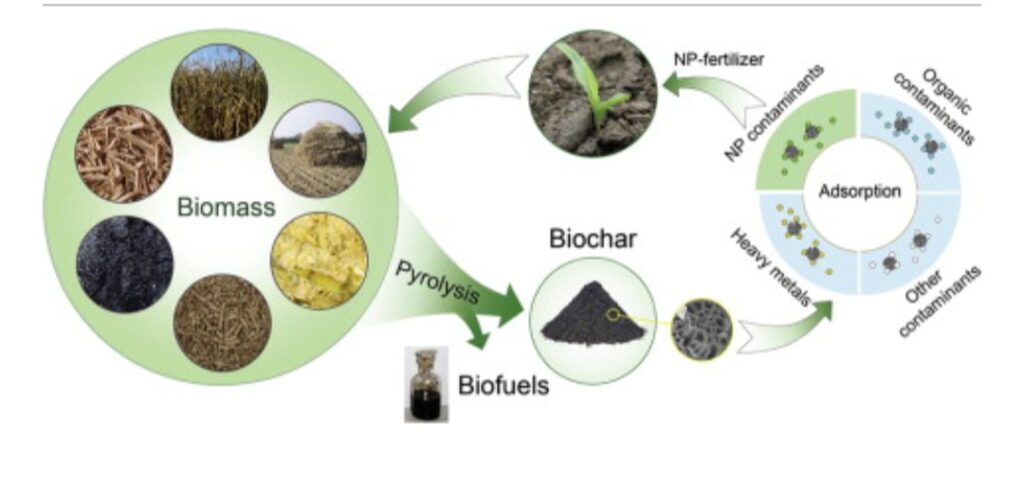

Biochar is a term for carbonaceous materials which are sustainable fuels, soil remediation, and carbon sequestration. Today, biochar has gained the global attention as a soil amendment and provide other benefits especially in agricultural production. It is a stable solid, rich in carbon, that is made from organic waste material or biomass that is partially combusted in the presence of limited oxygen.

By defination, Biochar is refered to as charcoal and carbon-rich material produced by partial oxidation (pyrolysis at ≤700 °C in the absence or limited supply of oxygen) of carbonaceous organic sources such as wood and plants, excluding fossil fuel products ( petroleum). It is rich in recalcitrant carbon that can persist in soils for years or decades, and even millennia.

Biochar has the ability to turn useless wastes into valuable products. This process is called valorization.

“Valorization ” means returning value to wasted materials. That value might be as an industrial additive, a new product, or even as a form of clean energy. The concept of valorization redefines the very idea of waste, applying instead a more dynamic understanding of how material changes over the course of its life cycle as a product.

WHAT IS BIOCHAR MADE UP FROM.

To have a better understanding of what biochar is and its properties, there is need to understand the following

1) What it was made from (i.e. the feedstock), and

2) The temperature at which it was made (i.e. 300-700°C).

COMMON FEEDSTOCKS

Biochar is a carbon-rich material that is made from biomass ( that is, materials derived from plants and animals called organic) through a thermochemical conversion process known as pyrolysis.

Thermochemical conversion can be applied to one or more kinds of waste, individually called “inputs” or “feedstocks.” Some common feedstocks include the following:

a. food waste

b. sewage sludge (also known as “bio-solids”)

c. agricultural by-products like crop straw and residues, animal manures, fruit pits, twigs, leaf litter, forestry wastes, and bagasse

d. cuttings and trimmings from parks and residences

These materials and methods used to produce biochar bring about the wide variety of chemical and physical properties possessed by biochar products.

Every thermochemical process results in a different final product (or “output”) when applied to a different feedstock. Three basic categories of outputs are derived from the thermochemical processes depending on the combination of feedstocks and methodologies used . Such outputs include: gas, liquid, and solid products. One methodology can lead to a combination of all three product types, depending on factors like temperature, air content, and pressure.

GAS PRODUCTS: Gas products are derived in a process called gasification. Gasification of waste biomass can result in industrially valuable gas products like light alkalines and olefins, typically derived from petroleum ( fossil fuel). These gases can be used directly for heat, power generation, electricity, transportation, as well as chemical and plastic production. It is also a potential source for pure hydrogen that can be used to generate green hydrogen energy.

LIQUID PRODUCTS: Liquid products can be made through thermochemical conversion in processes called Pyrolysis and catalytic upgrading. These two methods are used to convert waste biomass into bio-oil or bio-diesel. Pure hydrogen can also be produced in this way, which can be added to fossil fuels like gasoline or liquid natural gas to improve efficiency and lower overall GHG emissions. Other bio-fuels like mixed alcohols, ethanol, and methanol can also be made using this method.

SOLID PRODUCTS: When organic or inorganic waste are treated thermochemically, solid material or residue are usually left behind. The subjection of biomass to full pyrolysis result is biochar production..

TYPES OF THERMOCHEMICAL CONVERSION

As mentioned above, three main types of thermochemical conversion were mentioned.

- pyrolysis

- gasification

- combustion

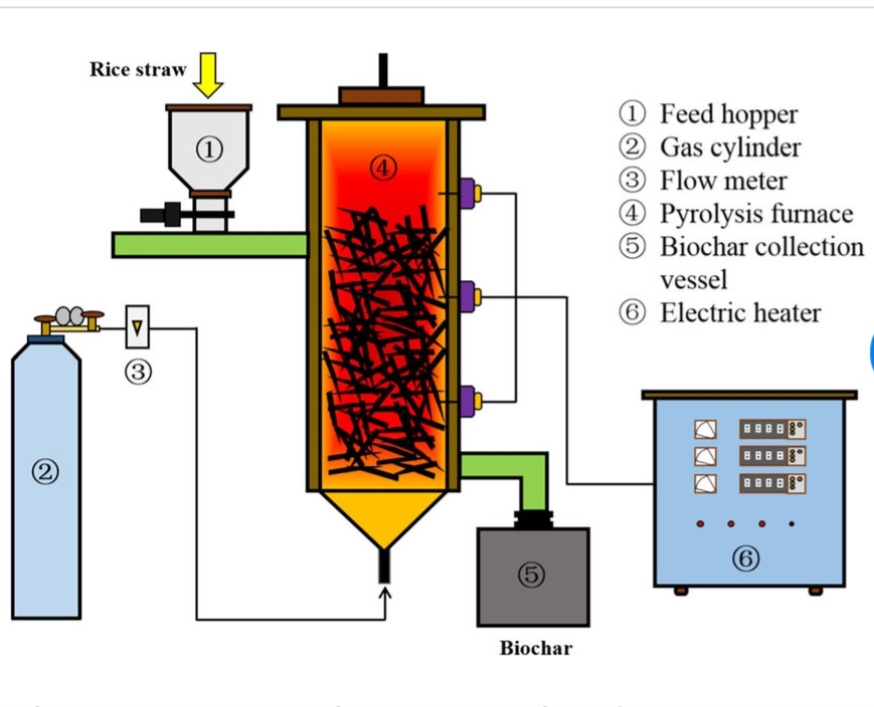

Each process requires different levels of oxygen to occur. PYROLYSIS : pyrolysis refers to the chemical decomposition of organic material when exposed to elevated temperatures in an atmosphere with restricted levels of oxygen. it occurs when there is none avialability of oxygen.

GASIFICATION: Occurs when there is a limited amount of oxygen, while

COMBUSTION : will only occur in the presence of oxygen.

IMPORTANCE OF BIOCHAR

1. It has been used by humans for over two thousand years as a soil enhancer or ammendments.

2. It helped to increase crop yields while sustaining essential soil biodiversity.

3. It improving soil health,

4. it is used to raise soil pH,

5. it is used to remediate polluted soils.

6. It can be used on its own or mixed with other soil amendments.

7. Carbon storage: Biochar is a very effective way to capture and store carbon in a solid state

8. Greenhouse gas emissions: Biochar can help lower greenhouse gas emissions by storing carbon.

9. Water treatment: Biochar can be used for water treatment.

10. Land reclamation: Biochar can be used for land reclamation in degraded soils.

11. It is used to increase soil aeration.

12. It is used to reduce nutrient leaching and reduce soil acidity.

13. It can be used for water retention in soil,

14. It is used as an additive for animal fodder.

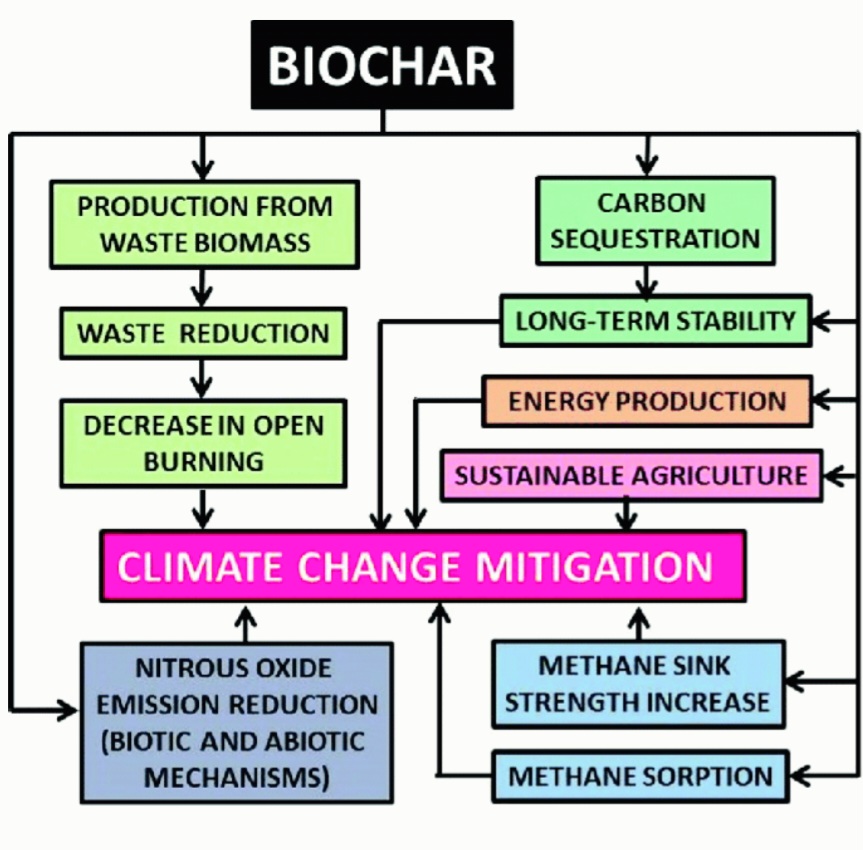

15. It may be a means to mitigate climate change due to its potential of sequestering carbon with minimal effort. The process by which it is manufactured do sequester a billion tons of carbon annually and hold it in the soil for thousands of years, where it is most beneficial.

17. It refroms irrigation and fertilizer requirements.

18. Fuel slurry: Biochar mixed with liquid media such as water or organic liquids (ethanol, etc) is an emerging fuel type known as biochar-based slurry. These slurries are fuels powering generators and providing electricity.

19. It enhances soil structure and aggregation

20. It reduces nitrous oxide emissions

21. It improves soil porosity

22. It improves soil electrical conductivity

23. It improves microbial properties

24. It is used for composting by promoting microbial activity, which accelerates the composting process. In addition, it also helps reduce the compost’s ammonia losses, bulk density and odour.

From all the bountiful benefits of biochar, it also comes with some negative effects such as over application harming soil biota, reducing available water content, altering soil pH, reduce pesticide efficacy and increasing salinity etc.

PRODUCTION OF BIOCHAR

Biochar, a charcoal-like substance made by burning organic material from agricultural and forestry wastes ( that is, biomass) in a controlled process called pyrolysis. During the process, contaminants are reduced and carbon is stored. Organic materials, such as wood chips, leaf litter or dead plants, are burned in a container with very little oxygen. As the materials burn, they release little or no contaminating fumes. The organic material is then converted into biochar, which is a stable form of carbon that cannot easily escape into the atmosphere. Energy or heat produced during the production process can be captured and used as a form of clean energy.

Clean feedstocks with 10 to 20 percent moisture and high lignin content are usually used such as those mentioned above, field residues and woody biomass. Contaminated feedstocks such as feedstocks from railway embankments or contaminated land, can introduce toxins into the soil, drastically increase soil pH and/or inhibit plants from absorbing minerals. The most common contaminants are heavy metals such as cadmium, copper, chromium, lead, zinc, mercury, nickel and arsenic and Polycyclic Aromatic Hydrocarbons.

PROPERTIES OF BIOCHAR

1. Biochar is by far more efficient at converting carbon into a stable form

2.It is a clean source of energy than other forms of charcoal.

3. biochar is black in colour just like charcoal.

4. It is highly porous.

5. It is light in weight.

6. It is fine-grained and has a large surface area.

7. Approximately 70% of its composition is carbon. The remaining 30% consists of nitrogen, hydrogen and oxygen among other elements.

8. Its chemical composition varies depending on the feedstocks used to make it and methods used to heat it up.

HOW BIOCHAR SEQUESTER CARBON AND MITIGATE CLIMATE CHANGE

Feedstocks used in making biochar ,that is plant biomass are composed of carbon within their tissues. If these plant biomass are allowed to decompose naturally, the decomposition process would release higher amounts of carbon dioxide to the atmosphere. But by heating the feedstocks and transforming their carbon content into a stable structure that does not react with oxygen during pyrolysis, biochar technology ultimately reduces carbon dioxide in the atmosphere, storing the carbon within the biochar product.

Biochar also mitigate climate change by enriching the soil, reducing the need for chemical fertilizers and improving soil health. It is environmentally friendly and also lowers greenhouse gas emissions. By enriching the soil and reducing heavy metal contamination, it stimulates the growth of plants, which consume carbon dioxide and produce safer food for consumption. The many benefits of biochar for both climate, the environment and agricultural systems make it a sustainable tool for regenerative agriculture.