Perlite, also known as “volcanic popcorn”, is a crop grow media made from volcanic glass. It is a naturally occurring mineral that exists as a type of volcanic glass, created when the volcanic obsidian glass gets saturated with water over a long time.

It can be called an amorphous volcanic glass which is dark black or grey in colour. Amorphous means that it does not have any definite shape or structure, unlike a crystal. It is pretty heavy and dense in its natural form with relatively high water content, typically formed by the hydration of obsidian. It has the unusual property of expanding when heated sufficiently. It is an industrial mineral, suitable “as ceramic flux to lower the sintering temperature”, and a commercial product useful for its low density after processing. It is a nonrenewable resource. The major producers are Greece, US, Turkey, and Japan.

Perlite can be Organic and at thesame time inorganic mineral. This is based on different perspectives.

From a chemistry perspective, organic compounds are those that contain carbon. Perlite does not contain carbon, so it is an inorganic mineral.

In the context of using it as a grow media, like in organic farming, the meaning or the word “organic” is different. It means materials that are naturally extracted from the earth and does not undergo significant chemical processing or does not contain chemicals.

This gives reasons why it is allowed by the National Organic Standards Board for use in certified organic agriculture. In the context of this, perlite is a safe “organic” additive used for farming.

PROPERTIES OF PERLITE

1. Perlite softens when it reaches temperatures of 850–900 °C (1,560–1,650 °F).

2. When water is applied to it, the water trapped in the structure of the material vaporises and escapes, and this causes the expansion of the material to 7–16 times its original volume. The expanded material is a brilliant white, due to the reflectivity of the trapped bubbles.

3. Unexpanded (“raw”) perlite has a bulk density of around 1100 kg/m3 (1.1 g/cm3), while typical expanded perlite has a bulk density of about 30–150 kg/m3 (0.03–0.150 g/cm3).

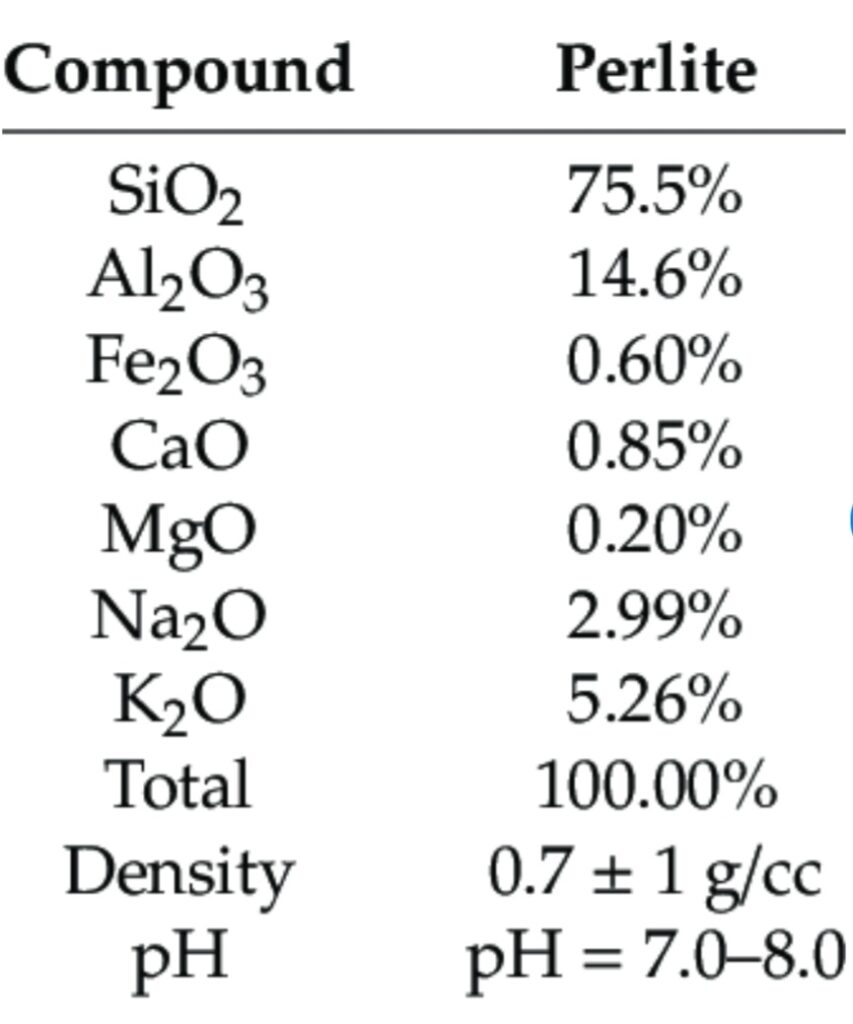

4. Typical analysis of perlite include:

70–75% silicon dioxide: SiO2, 12–15% aluminium oxide: Al2O3, 3–4% sodium oxide: Na2O, 3–5% potassium oxide: K2O, 0.5-2% iron oxide: Fe2O3, 0.2–0.7% magnesium oxide: MgO, 0.5- 1.5% calcium oxide: CaO and 3–5% loss on ignition (chemical / combined water)

5. Perlite can be safely disposed of through existing sewage systems, although some pool operators choose to separate the perlite using settling tanks or screening systems to be disposed of separately.

6. It has a thermal and mechanical stability

7. It is non-toxicity

8. It is highly resistance against microbial attacks and organic solvents

9. It is highly permeable and it has low water retention property

10. It can helps prevent soil compaction.

CHARACTERIATICS OF PERLITE

PHYSICAL CHARACTERISTICS

1. Perlite is encompased with enclosed air pockets, expanded perlite is very lightweight with a particle and BD of 0.7 and 0.1 g/cm3, respectively.

2. It is very porous and can hold 3–4 times its weight in water.

3. Perlite has very low bulk density ( BD). It is probably the most used substrate for green roofs , however, one has to consider the high weight of the moist substrate.

4. Perlite is probably a medium ingredient that has the highest air-filled porosity compared to other grow media.

5. Perlite exist in different fraction. These fractions have different water retaining capacity. For example, water retained at −10 kPa is much higher for the coarse fraction (0.5–1.0 mm diameter) than for the fine fraction (0.25–0.50 mm diameter) of expanded perlite. This difference in water holding capacity between the coarse and fine fractions indicates that most of the water is held by the coarse particles in internal pores. However, it is not explained by the volume of internal porosity alone. The decrease in water content with decreasing matric potential is moderate relative to sand and stone wool.

6. Saturated hydraulic conductivity (Ksat) is a measure of how easily water can pass through saturated grow media. It depends on particle diameter. The saturated hydraulic conductivity of perlite typically ranges between 0.1 to 1 cm/min depending on the particle size, with coarser perlite having a higher conductivity than finer perlite. For example, coarse perlite (1-7.5mm) can have a saturated hydraulic conductivity around 1 cm/min while fine perlite (0-1mm) may be closer to 0.01 cm/min. For commercial perlite of 0–4 mm diameter with 50% of the particles smaller than 0.5 mm, saturated hydraulic conductivity was 0.3 cm/min . In a study, a reduction of two orders of magnitude in the hydraulic conductivity was obtained as the matric potential decreased from 0 to −30 cm H2O. This change is moderate when compared to sand.

7. Due to perlite’s excellent physical characteristics, it is frequently used as a component in mixtures based on organic substrates such as compost. By this, the positive biological features of such media can be maintained for a relatively long period, while preventing compaction.

8. Perlite is physically stable and retains its shape even when pressed into the soil.

9. It is incredibly porous and contains pockets of space inside for air

10. It can retain some amount of water while allowing the rest to drain away

CHEMICAL CHARACTERISTICS

1. Perlite is neutral with a pH of 7.0–7.5, but it has no buffering capacity and contains no mineral nutrients.

2. The inert nature and neutrality of perlite make it a favorable medium for assessing the usefulness of various forms and levels of nutrients.

3. When the pH is low, there is a risk of toxic Al release into the solution.

4. chemical composition of perlite:

70-75% silicon dioxide

Aluminum oxide

Sodium oxide

Potassium oxide

Iron oxide

Magnesium oxide

Calcium oxide

3-5% Water

5. It contains no toxic chemicals and is made from naturally occurring compounds found in soil

SOURCES AND PRODUCTION

Perlite is a non-renewable resource. The world reserves of perlite are estimated at 700 million tonnes.

Perlite world production, led by China, Turkey, Greece, USA, Armenia and Hungary, summed up to 4.6 million tonnes in 2018. The confirmed resources of perlite existing in Armenia for example, amount to about 150 million m3, whereas the total amount of projected resources reaches up to 3 billion m3. Considering the specific density of perlite with 1.1 ton/m3, the confirmed reserves in Armenia amount to 165 million tons.

Other reported reserves include: Greece – 120 million tonnes, Turkey, USA and Hungary – about 49-57 million tonnes.

Perlite is one of the several components often found in soilless growing material. It is refered to as a volcanic popcorn.” ( literal description). It is rich in water, it pops when heated to very high temperatures, exactly like popcorn. It is an ultra-lightweight mineral, absorbent, and porous. This volcanic material is processed into perlite balls by crushing natural perlite glass and then baking them in industrial ovens. The crushed volcanic glass is then run through a screen and then heated quickly to a super high temperature of 900°C (around 1650°F). The mineral structure is softened by the heat, allowing the water trapped inside to expand into steam in a bid to escape. This result to a material that is sterile, retains up to 3-4 times its weight in water and is extremely lightweight. When perlite is heated, it pops rather like popcorn until it looks a bit like white polystyrene.

This product formed during the process of formation leads to expansion of the mineral. It is not usual for perlite pieces to expand between 7 and 16 times their original size and volume, creating those lightweight faux-styrofoam balls.

The foamy balls have a lot of porous openings inside them and are clean, sterile and generally stable. It can hold its shape with ease in the soil without crumbling.

TYPES AND GRADES OF PERLITE

Perlite manufactured for gardening and horticulture purposes are produced in various grades, the most common being 0–2.0 and 1.5–3.0 mm in diameter. The various grades differ in their physical characteristics.

There are three types of graded depending on the size of the individual particles:

1. Coarse Perlite

This has the highest porosity and draining capabilities. It is best suited for succulent plants and orchids. It is also least affected by winds. But it does not work its way up to the topsoil very easily.

2. Medium Grade Perlite

This straddles the middle ground regarding aeration and draining. It is best suited for potted seeds and seedlings.

3. Fine Perlite

This is the lightest grade, best suited for starting seeds and root cuttings. Fine particles of perlite can also be scattered lightly on top of the soil in gardens and lawns.

USES OF PERLITE

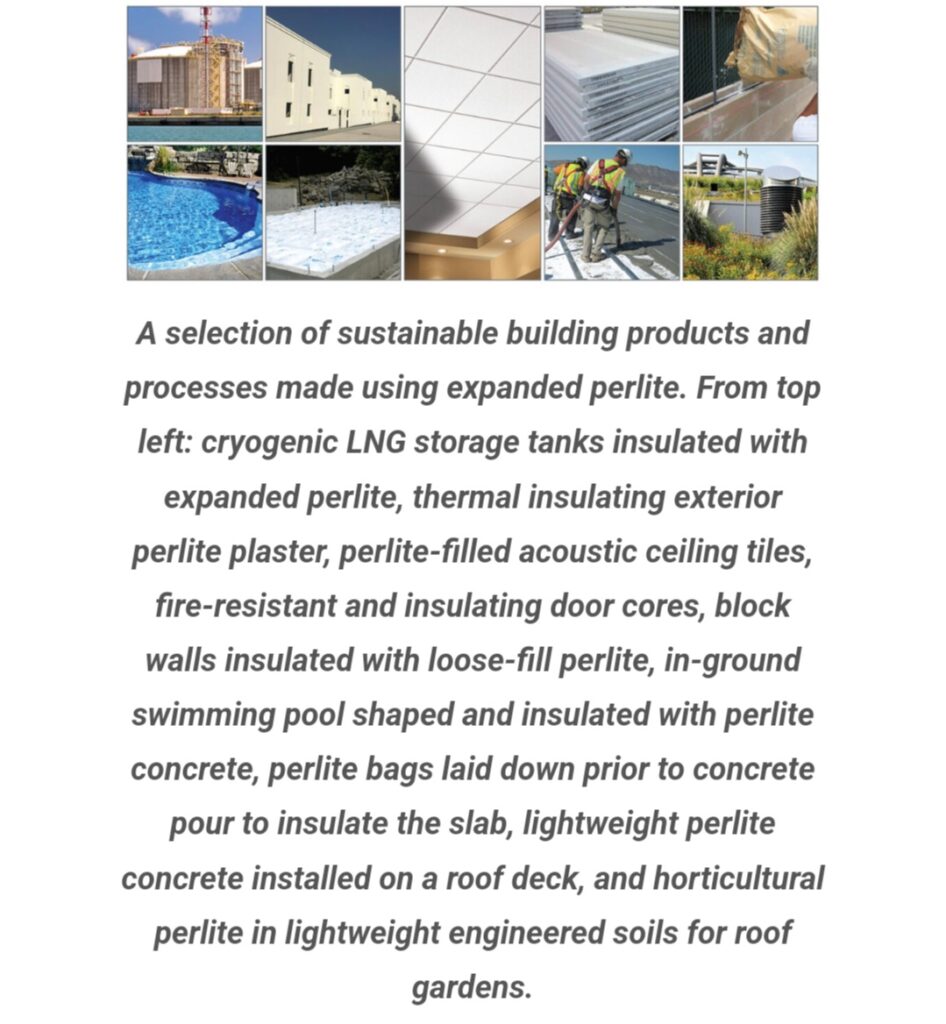

1. CONSTRUCTION AND MANUFACTURING:

In the construction and manufacturing fields, due to its lightweight, it is used as plasters, concrete and mortar, insulation and ceiling tiles.

2. It may also be used to build composite materials that are sandwich-structured or to create syntactic foam.

3. Perlite filters are fairly common in filtering beer before it is bottled.

4. Small quantities of perlite are also used in foundries, cryogenic insulation, and ceramics (as a clay additive).

5. It is also used by the explosives industry.

6. AQUATIC FILTRATION: Perlite is currently used in commercial pool filtration technology, as a replacement to diatomaceous earth filters. Perlite is an excellent filtration aid and is used extensively as an alternative to diatomaceous earth. The popularity of perlite usage as a filter medium is growing considerably worldwide. Several products exist in the market to provide perlite based filtration. Several perlite filters and perlite media have met NSF-50 approval (Aquify PMF Series and AquaPerl), which standardizes water quality and technology safety and performance.

7. BIOTECHNOLOGY: Perlite is widely used in biotechnological applications. It was found to be an excellent support for immobilization of biocatalysts such as enzymes for bioremediation and sensing applications due to its thermal and mechanical stability, non-toxicity, and high resistance against microbial attacks and organic solvents,

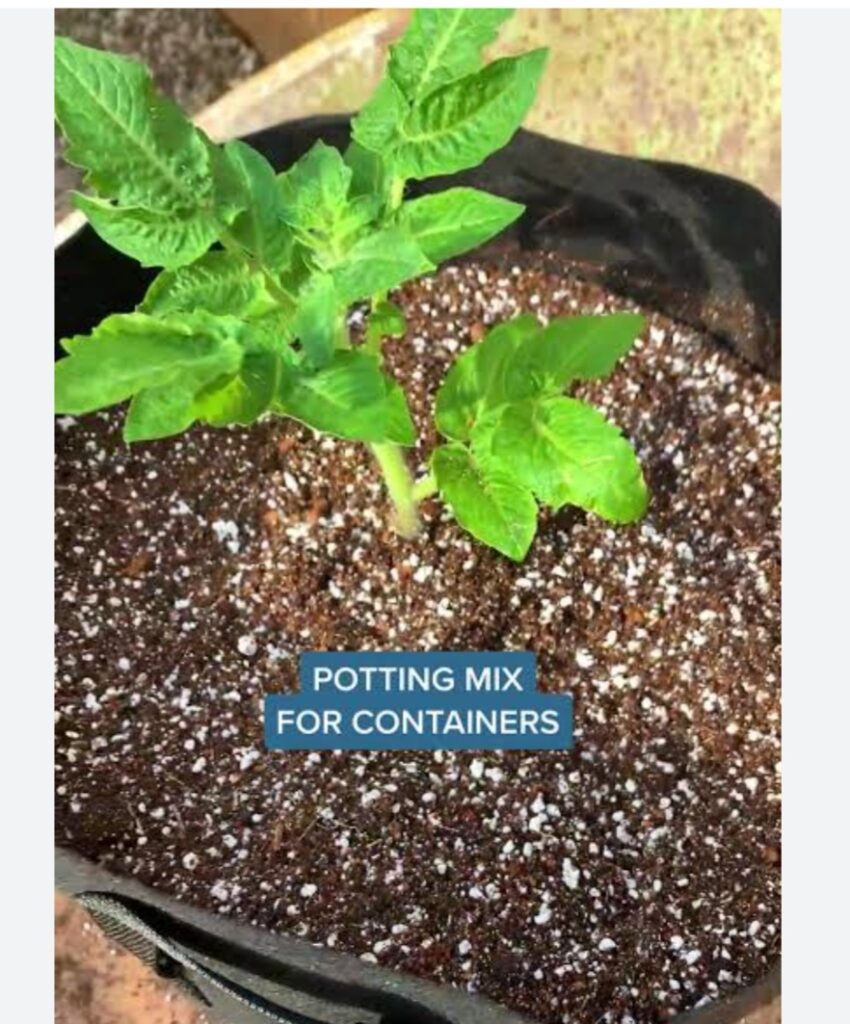

8. AGRICULTURE:

In horticulture, perlite can be used as a soil amendment or alone as a medium for hydroponics or for starting cuttings. When used as an amendment, it has high permeability and low water retention and helps prevent soil compaction.

9. COSMETICS: Perlite is used in cosmetics as an absorbent and mechanical exfoliant.

9. SUBSTITUTES: Perlite can be replaced for all of its uses. its Substitutes include:

a. Diatomite, used for filter-aids

b. Expanded clay, an alternative lightweight filler for building materials

c. Shale, Pumice, Slag

d. Vermiculite : many expanders of perlite are also exfoliating vermiculite and belong to both trade associations

10. Perlite is added to soil mediums for its water retention but more importantly for its ability to aerate soils due to its high porosity level.

11. AERATION: Plant cells need oxygen, whether Arial or underground. It is used by green parts of plant during the process of photosynthesis.

While the underground parts like the root system has to absorb oxygen from the soil. Thus, use of perlite can help aerate the soil and growth of strong root systems. It contains great air pockets meaning that perlite is great for root systems development. When the soil gets packed down, the air pockets are lost. But since perlite is a harder mineral, it retains its shape, keeping those air pockets around for the roots.

12. DRAINING: Water is an important commodity needed for survival. For plants, excess water in the soil is detrimental and can lead to drowning and death of the plant. The plant root system becomes starved of oxygen, causing eventual death. Therefore, proper drainage is required to allow empty air spaces to remain in the soil.

Adding perlite to the soil improves its drainage capabilities, as it has excellent filtering and water draining capabilities. The presence of all those pores allows most of the excess water to drain off.

13. FOR ROOT CUTTINGS: Perlite encourages root growth much better than just plain water. Seeds or cuttings can be germinated by placing them in an air-filled Ziploc bag contained moistened perlite.

It also stimulates root growth, and prevents drowning by helping drain excess water away from the cuttings. It can be used with rooting compounds.

14. STANDALONE GROWING MEDIA: Perlite is a decent option in some instances as a hydroponic medium. But it is not suitable for high water settings, like deep water culture, or ebb and flow systems.

15. In mixture with other growing media. Perlite is commonly mixed with vermiculite in equal amounts (50-50). This greatly solves the water-retaining issue of Perlite while improving the water-holding capacity of vermiculite, making it able to use in the water-rich systems.

STERILIZATION, REUSE, AND WASTE DISPOSAL

Perlite is a stable, sterile, inert materia produced at very high temperatures. Chemically, it can last for several years and its stability is not much affected by acidity or microorganisms.

After use, perlite can be recycled. This recycling process does not cause any negative environmental effect. When used perlite is reused without sterilization or treatment as a grow media, this poses a severe risky of media compaction, salt buildup, and pest contamination.

Also, it is costly to replace used perlite with new media as this increases cost of production and at thesame time farmers might not recoup back the expense from the sale of produce derived from the use of perlite.

To overcome this problems, farmers can use sterilization, solarization and heat treatment method so as to reuse the product. This comes with several advantages over use of new perlites

STEAM STERILIZATION

Perlite can be steam sterilized before Reuse as grow media so as to safeguard against pathogen contamination. This type of treatment requires the use of expensive steam generators. A disadvantage of this method is that it may not be adequate to restore perlite’s loose structure and to reduce accumulated salt content of the perlite.

In a reseach carried out to determine the effect of cleaned and disinfected used perlite over new perlite on the growth of tomatoes (Lycopersicon esculentum ), it was diacovered that the cleaned and disinfected used perlite is more economical to use than the new perlite and also, there was no negative effect on yield of the crop.

HOT WATER TREATMENT

In a research carried out by Hanna in 2005, the research was carried out for 8 years on the effect of heat treatment of perlite to produce tomatoes in bags, Hanna used recycled perlite and treated it with hot water (13.25 L water/18.9 L perlite) at temperatures reaching 93.3°C to leach excess salts and disinfect the medium. These perlites were used twice within a year for commercial tomato production in bag (18.9 L) culture. After harvesting, he separated the roots of the previous crops from the whole plant and discovered that the treatment raised the media temperatures above limits, resulting in the killing of several fungi and nematodes and significantly reduced salt contents (Electrical Conductivity (EC), NO3–N, and K were reduced by 43%, 50%, and 47%, respectively) with no noticeable change in physical properties [i.e., particle size distribution (PSD)] over the 8 years.

Other studies carried out in 2008 and 2016 reveals that

perlite has a natural plasticity property making it prone to mechanical compression and disintegration. This contrast the result of Hannas on the physical properties of perlite.

From these researches, it can be deduced that after cleaning and disinfecting used perlite, recycling it saves 56% of the cost to replace it with new media. Also, higher produce yield with heavier tomato fruit were realised than with new perlite. Therefore, it can be concluded that the observed yield from the recycled perlite was attributed to the collective effect of salt reduction, media disinfection, and the presence of an optimum level of nutrients. It often takes time to build up nutrients to an optimum level in new perlite. Thus, used perlite can be cleaned and disinfected and recycled for many years due to it’s non organic nature and physical and chemical stability.

Another study had proven that recycled perlite and peat–perlite mix were more suppressive against Fusarium oxysporum f. sp. radicis lycopersici than the newly unused media. Another efficient disinfecting method for perlite is by solarization of the growing bags within the greenhouse.

SAFETY PRECAUTIONS WHEN USING PERLITE

1. Perlite contains silicon dioxide, therefore, goggles and silica filtering masks are recommended when handling large quantities.

2. The Occupational Safety and Health Administration (OSHA) of USA has set the legal limit (permissible exposure limit) for perlite exposure in the workplace as 15 mg/m3 total exposure and 5 mg/m3 respiratory exposure over an 8-hour workday.

3. The National Institute for Occupational Safety and Health (NIOSH) has set a recommended exposure limit (REL) of 10 mg/m3 total exposure and 5 mg/m3 respiratory exposure over an 8-hour workday.

4. Perlite Toxic: Perlite is a naturally formed material and, if excess quantities are used and proper ventilation is not provided, it will be toxic.

5. Perlite and vermiculite are excessively dusty and inhalation of this dust can cause irritation in the respiratory tract or skin irritation. So, in an abundance of caution, users should wear gloves and a mask.

DIFFERENCE BETWEEN PERLITE AND OTHER GROW MEDIA

PERLITE VS. VERMICULITE

There are several differences between perlite and vermiculite. Both perlite and vermiculite can be found in soilless or potting mediums and both come in various grades but which is better and really depends on specific growing needs. The most distinct difference is their water retention capability. Perlite may retain water 3-4 times its weight, but vermiculite absorbs up to 16 times its weight.

Vermiculite and perlite are both volcanic material but unlike perlite, it contains minerals such as magnesium, iron, and aluminum. Vermiculite also has traces of minerals that can be beneficial to plants but not in such an amount that supplemental nutrients will not be necessary.

As a farmer, if water retention is the goal for selection, vermiculite is more preferred. But if better aeration and drainage are most important, perlite is the best choice.

PERLITE VS. STONEWOOL

Perlite is a lightweight, volcanic glass material that primarily functions to improve drainage and aeration in a growing medium by adding air pockets, while stone wool is a fibrous material made from melted rock, offering a more balanced combination of water retention and aeration, often used as a standalone growing substrate for plants without needing additional amendments like perlite. Essentially, perlite is typically used as an additive to enhance existing soil, while stone wool can be used on its own as a complete growing medium.

Perlite is a naturally occurring volcanic glass, while stone wool is manufactured from melted rock spun into fibers. Perlite has a granular, popcorn-like texture with large air pockets, whereas stone wool has a fibrous, web-like structure.

In addition, perlite is often mixed with other potting mediums like soil or coco coir to enhance their drainage, while stone wool is typically used as a complete growing medium on its own, particularly in hydroponic systems.

PERLITE VS. PEAT

Perlite and peat moss are both used in potting mixes and have similar physical properties. They differ in the following ways:

Perlite is produced from

Volcanic glass that expands when heated. The production is usually uniform while peat moss is an organic material that decays over time. The production varies. Perlite can

hold 3–4 times its weight in water while peat moss has

high moisture content

Perlite is an important grow media that helps with drainage and loosening heavy soil, while peat moss can improve plant growth and nutrient uptake