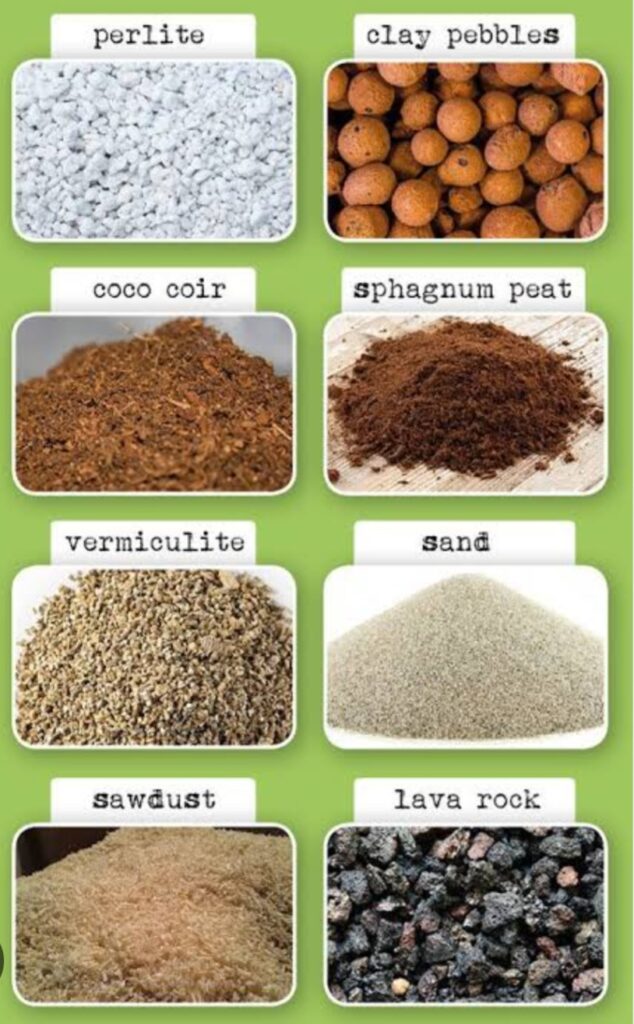

Plant growth media, also known as a substrate or potting mix, is a material that supports plant growth by providing water, nutrients, air, and structure. They include: Soil, Vermiculite, Rock wool, Perlite, Peat moss, Bark, Coir, Clay pellets, and Expanded clay etc.

The type of growing media used depends on the environment and the specific needs of the plants being grown.

Rockwool also known as stone or mineral wools, is a lightweight hydroponic substrate made from spun molten basaltic rock. It is a popular and efficient growing medium for various crops, including tomatoes, peppers, melons, cucumbers, strawberries, herbs and cut flowers and lettuce, in commercial and smaller hydroponic setups.

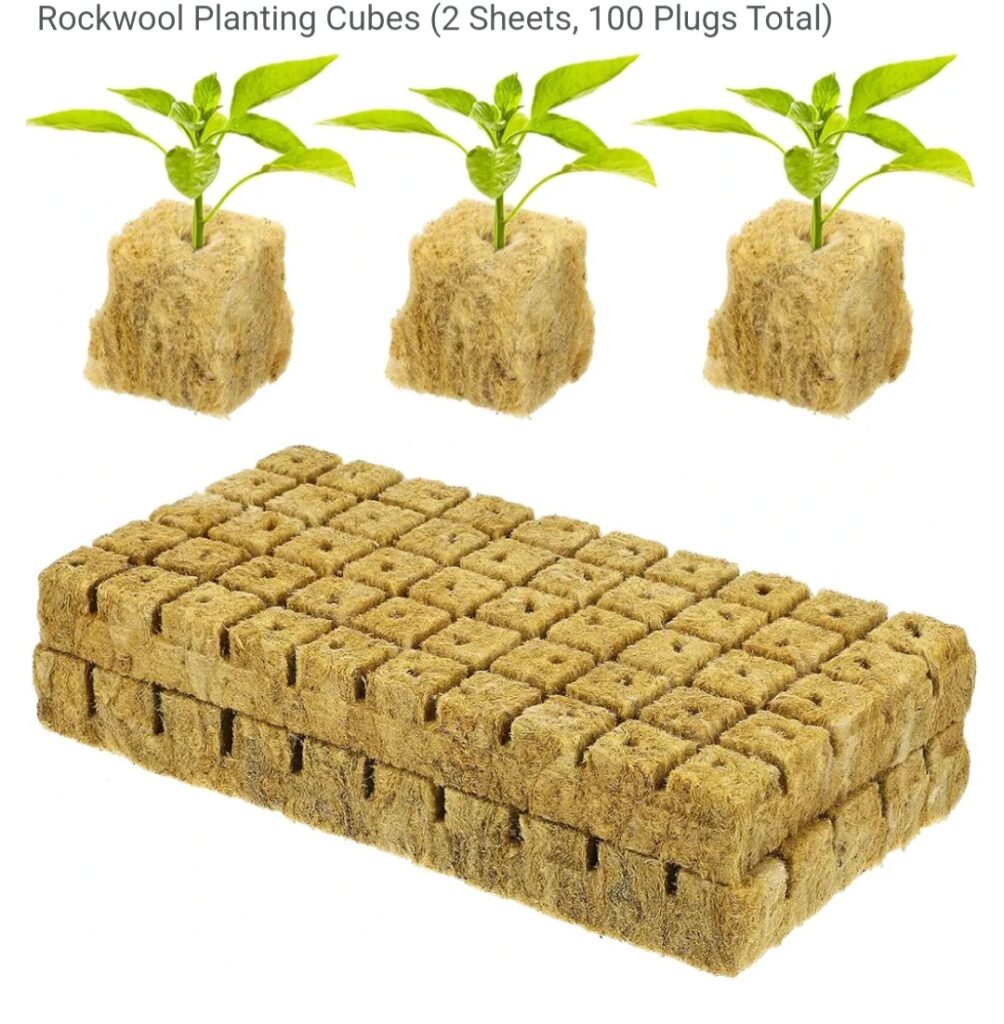

It is formed by spinning molten basaltic rock into fine fibers, which are then formed into cubes, blocks, slabs, or granules.

It is a natural product due to the fact that it originates from rock.

Hydroponics: Rockwool is a popular soilless growing medium used in hydroponics, a method of growing plants without soil.

ORIGIN OF ROCK WOOL

Stone wool was discovered on the islands of Hawaii around the beginning of the nineteenth century and occurs as a natural byproduct of volcanic activity. Grodan invented and debuted stone wool as a growing media in 1969.

The use of rock wool originally started as a thermal insulation material in the construction industry, it is lightweight but highly aerated. It helps keep heat inside buildings, easy to handle, cut and install. Towards the end of the 1960’s trials were carried out in Denmark to test the possibility of using stone wool as a substrate for hydroponic plants and since then, rock wool has being seen as a growing media for continious development and improvement.

Today, Rock wool is used by both large scale commercial producers and small scale crop growers. Apart from the selection of different sized rock wool cubes, blocks and plugs for propagation, growing slabs and granulated rock wool exist for the production of longer term crops and fruiting plants.

CHARACTERISTICS OF ROCK WOOL

The way in which the molten rock fibres are stacked and the density inside the rock wool product determine the properties of the growing media.

Some of its characteristics include:

1. It has high moisture holding capacity

2. It is highly porous making it to be well aerated or air filled. 3. It has good moisture gradient from the top to the base of the cube or growing slab.

4. One of the most important characteristics of rock wool is that plants are still able to extract water for growth at very low moisture tensions in the media. That means that plants can easily extract water when the rock wool is saturated from recent irrigation and when the rock wool slab has dried down considerably and lost as much as 70-80% of its moisture content, levels which in other growing media would cause severe wilting in the crop.

5. The moisture gradient between the top and base of a rock wool growing slab, cube or block is also one of the important characteristics of the product. After irrigation, the base of the rock wool is always saturated with plenty of moisture, while the upper layers of the rock wool are held in a drier condition and hence have access to plenty of aeration and oxygen for root uptake and respiration. It is this moisture gradient from top to bottom of the rock wool material which make it such a good hydroponic substrate, but at the same time growers who are not aware of this property can make the mistake of thinking the rock wool is too dry on the surface and over irrigate the plants despite having plenty of nutrient solution held deep down in the root system.

These properties of the rock wool can easily be altered, making rock wool products available for different applications by growers. For example, the product can be designed to maintain a slightly drier root zone and helps steer crops away from overly vegetative growth, while another may be designed for ultra quick root growth and development. This allows growers to choose the rock wool product which best suits their system, crop, irrigation strategy and environment to maximise plant growth and development.

6. Irrigation of rock wool is a little different to other solid substrates because of the way the material is manufactured to have just the right degree of moisture gradient and because it does give a limited root zone for plants that eventually grow fairly large. For this reason, most rock wool products are best irrigated with short, frequent applications of nutrient solution, with just enough at each irrigation for the rock wool to reach `field capacity’.

Field capacity is a term which means the substrate has drained fully but is still holding a good level of moisture for the plant roots to access until the next irrigation. At each irrigation, there should be some drainage from the rock wool material, however this should not be excessive. Having around 10-35% of the nutrient solution fed to the plants drain from the rock wool as each irrigation is considered optimal. This amount of drainage of solution flushes fresh nutrient solution right through the rock wool slab and usually keeps the EC in the slab fairly stable.

7. ELECTRICAL CONDUCTIVITY (EC) management: Rock wool has very low electrical conductivity, meaning it is considered a poor conductor of electricity due to its primarily fibrous, porous structure composed of volcanic rock fibers, making it a good insulator in electrical applications. However, its conductivity can slightly increase depending on factors like moisture content and the presence of conductive additives.

Rock wool electrical conductivity directly increases with moisture content, meaning that as the rock wool absorbs more moisture, its electrical conductivity also increases. This means that, the higher the electrical conductivity, the greater the moisture content within the rock wool material.

It is important to check the rock wool EC at the root zone just as it is with any other substrate. Rock wool does not contain any naturally occurring minerals or salts which may influence EC levels. The EC of the nutrient solution inside the growing substrate changes as plants extract different ratios of water and nutrients from the root zone. Therefore, it is important to careful monitor and control both the EC and pH in the nutrient solution in recirculating rock wool systems just as it is important with other growing media.

Under warmer growing conditions, plants can extract high levels of water from a nutrient solution, thus increasing the EC rapidly and requiring the addition of greater amounts of top-up water in the nutrient reservoir. Under cooler and/or humid conditions, the EC may drop as plants extract nutrients but do not require as much water, making frequent checks and adjustment of EC levels important for maintaining growth control.

8. Rockwool is stable and has no adverse environmental impacts. The product can typically be disposed of in an ordinary landfill (local regulations may apply).

9. Stone wool growing media can be used for cultivation of plants in Controlled Environment Agriculture (CEA). It has neutral pH and has air pockets that make it suitable for hydroponics. These air pockets supply oxygen and moisture to plant root zone. This type of soilless growing media is ideally suited to indoor cultivation, from vegetables and floriculture to medicinal crops.

BENEFITS OF USING ROCKWOOL

1. LIGHTWEIGHT AND ABSORBENT:

Rockwool is lightweight, making it easy to handle and highly absorbent, allowing it to hold a significant amount of water and nutrients.

2. EFFICIENT WATER AND NUTRIENT DISTRIBUTION:

It provides uniform distribution of water and plant nutrients, ensuring plants have access to what they need.

3. CONTROLLED ENVIRONMENT:

As rockwool is inert and contains no nutrients, growers have complete control over the nutrient solution provided to the plants.

4. IMPROVED ROOT ZONE TECHNOLOGY:

Rockwool’s structure promotes healthy root development and oxygenation, leading to improved plant growth.

5. VERSATILE:

It can be used for a wide variety of crops, including vegetables, fruits, herbs, and flowers.

6. COST-EFFECTIVE:

Rockwool is a relatively inexpensive and efficient hydroponic substrate.

7. pH AND EC LEVELS:

Because rockwool is inert, growers need to carefully monitor and adjust the pH and EC (electrical conductivity) of the nutrient solution, as there is no buffering capacity from the substrate itself.

8. DISPOSAL:

The disposal of mineral wool can pose environmental challenges, so proper disposal methods are crucial. It can easily be recycled into raw materials for products such as new stone wool and bricks.

9. IMPROVE ROOT ZONE: Rock wool can easily be used by smaller hydroponic growers who want to take advantage of improved root zone technology.

10. Stone wool has a unique fibre content which makes the cultivation on stone wool growing media very easy to control. The grower can administer the precise amount of water and nutrients the crops need in a very directed and controlled manner, to achieve optimal growing results. Waste becomes a thing of the past.

11. Efficient use of water and nutrients keeps yield per square metre high, and energy consumption per unit of product low.

12. Rock wool is sterile and inert and thus makes an excellent seed germination and growing medium. It is a growing medium for germinating and raising seedlings due to its high aeration and good water retention properties.

13. It has high success rates,

Sterile, affordable and easy to use.

14. By increasing the time between irrigations and allowing the EC in the root zone to increase, the rock wool slab dry back. This pushes plants such as tomatoes into a more generative state with less leaf growth and more assimilate being directed into the fruit. A higher level of moisture maintained in the rock wool and a lower EC pushes the plants towards more vegetative growth rate. Skilful growers use these techniques in rock wool growing media to direct their crop and control leaf, flower and fruit growth at different times.

15. Rock wool, being a ‘sterile’ product (only directly after production) does not contain any naturally occurring beneficial microbial populations when first planted out, however research has shown that microbial life does develop in rock wool substrates in the same way as other more ‘organic’ mediums such as peat and coco. This build up of beneficial microbial populations however is generally slower in rock wool as there are initially limited carbon sources for the microbes to feed on.

16. As root systems develop and produce organic exudate, microbial life inside rock wool gradually build, however rock wool can be inoculated with microbial products to assist this process and help develop a healthy root zone.

In addition, the high level of oxygenation in a well managed rock wool system helps with the establishment and multiplication of beneficial microbe populations.

17. Rock wool, an essential rock does not decompose, fracture or break down over time, hence growers can use it for many successive crops, that is, it is reusable.

18. Stone wool is a highly suitable growing medium for Controlled Environment Agriculture, or indoor cultivation environments. This closed environment, in combination with stone wool and automated growing systems, allows for every aspect of the plants’ lighting, nutrition and irrigation to be controlled by the grower. Stone wool products are designed for precision growing and are fully compatible with the sensors and automation tools utilized in a data-driven cultivation strategy.

19. Stone wool is much less likely to be contaminated by fungi, yeasts and bacteria as well as insects and microbes that feed and live on carbon-based organic matter in coco coir and soils. Therefore enhancing crop quality.

HOW TO MAKE STONE WOOL

Rockwool is the product of molten rock which has been spun around at high heat (similar to fairy floss). The result is a light material with thousands of tiny cavities that help store water and air.

Stone wool is made from basalt, a solidified lava spewed from the innermost depths of the earth. The extracted basalt and raw stone material is re-liquefied in furnaces at a temperature of 2700°F ( 1500°C). The molten rock is injected with air and spun into a fibrous, yet light consistency resembling spun sugar. The material is treated with a hydrophilic binder to facilitate liquid absorption, which ensures even distribution of water and nutrients upon use. Next, it is congealed in a hardening kiln using hot air at > 390°F (200°C) after which it is compressed into wool packets.

The stone wool packets are then cut into a graduated series of sizes and shapes—from small-sized plugs to larger blocks and slabs, each designed for various crops and for different stages of crop production. The finished products are wrapped in a special film that blocks UV light and limits the growth of algae on the growing media surface.

The result is a clean and uniform growing medium with plenty of space for roots to grow and access moisture, nutrients and oxygen from well-distributed irrigation. Clean stone wool is designed to retain water as well as air, while also promoting healthy drainage from top to bottom – unlike soil-based media that are prone to compaction and certain soilless media that can become hydrophobic (water-repelling) if allowed to dry out.

ADVANTAGES OF ROCK WOOL

1. Rock wool has many advantages for hydroponic production: The manufacture of the rock wool fibres from molten rock and plastic wrapping of growing slabs ensures the product is sterile, and free from weed seeds, pests and pathogens.

2. High quality rock wool brands are consistent in quality and do not decompose or break down over time in the way that many other natural growing substrates do.

3. Rockwool maintains it physical properties over time and with successive crops. It

is light weight and thus easy to handle and shift into place, once fully irrigated however it becomes heavy and provides stability to the crop.

4. Rock wool comes in a convenient range of sizes from small 2-3 cm propagation plugs joined in sheets for direct sowing crops such as lettuce and other seedlings, to large cubes of over 10cm for more advanced transplants.

5. The plugs are often used for cuttings where they maintain the ideal levels of aeration and moisture for rapid root development.

6. Rock wool can be inoculated with beneficial microbes such as Trichoderma in much the same way other substrates like coco are, however more frequent applications of microbial products are recommended with rock wool substrates.

7. Most rock wool products and reliable brands do not have any major influence on the EC, pH or composition of the nutrient solution applied. Since rock wool provides no naturally occurring nutrients a well balanced nutrient product applied will give optimal growth.

8. Rockwool is manufactured to give a close to ideal level of moisture and aeration in the root zone. This helps prevent over watering and root suffocation from a lack of oxygenation.

9. Rock wool can be used for successive crops as its structure does not tend to break down rapidly with use or over time. some commercial tomato growers use good quality rock wool for as many as 6 successive crops with use of steam sterilisation to control root pathogens between plantings.

10. The products and growing slabs come ready to use, the substrate only needs to be thoroughly wetted before planting.

11. Rockwool can be monitored with a water content meter which gives accurate measurement of the water content, EC and temperature in the plant’s root zone environment. These assist with fine turning the application of nutrient solution to just the right level for each stage of growth.

DISADVANTAGES OF ROCK WOOL

1. Rockwool is bulky to transport and store, unlike coco slabs which can be highly compressed and then expanded with water before use.

2. It needs to be placed on a fully levelled surface to allow the moisture gradient inside the product to be even and prevent any saturation or overly dry patches from developing.

3. Despite being usable for more than one crop, and some recycling programs developed for used rock wool, disposal can still be a problem for many growers as rock wool does not decompose or break down over time.

4. Rockwool fibres can irritate the skin and a face mask is recommended if handling granulated rock wool or disposing of old rock wool products.

5. Rockwool contains no naturally occurring nutrients (coco often contains levels of potassium and sometimes other minerals which are used to pre condition the substrate), hence the plants are totally reliant on a well balanced and complete hydroponic nutrient solution at each stage of growth.

6. Being an inert substrate made from rock, rockwool does not contain naturally occurring growth stimulants such as humic acid, other organic compounds or naturally occurring beneficial microbes, although these can be added with the use of good quality hydroponic supplement products.

7. New or inexperienced growers need to determine the right frequency and amount of irrigation for rock wool systems as this can differ somewhat from other substrates such as perlite and coco. Therefore, to use rockwool, there is need for technical know- how.

HOW MOISTURE IS MAINTAINED IN ROCK WOOL PRODUCTS

Standard rock wool products are highly porous, meaning they drain freely after irrigation and contain 80% nutrient solution, 15% air pore space and 5% rock wool fibres, although these ratios differ slightly between rock wool brands and products. A typical rock wool slab, such as those used for tomatoes and other fruiting crops, contains around 9 litres of nutrient solution immediately after irrigation, despite the drainage holes allowing free drainage of excess solution.

During irrigation of rock wool, it should not be left sitted in the nutrient solution that makes it completely saturated from top to bottom like a sponge. It is important for users of the rock wool to allow it drain completely so that excess nutrient solution applied can be absorbed from the slab or cube under the pull of gravity. By doing this, fresh air will be drawn into the top layers of the material, providing fresh oxygenation for the root zone.

When rock wool are allowd to drain freely, over watering becomes more difficult.

MECHANISMS OF GROWING CROPS IN STONEWOOL

Stone wool cultivation system consists of plugs, blocks and slabs. The plug is used for sowing. It is the hole where the seed grows into a seedling. Then the seedling with the plug is transplanted in a block in which it is grown into a full-fledged young plant. The full-fledged young plant with block is then placed on the slab for growing to maturity and producing fruits.

USING ROCK WOOL TO RAISE SEEDLINGS

To germinate seeds in rockwool, make sure that the rockwool cubes have been fully soaked, place 2-3 seeds in the hole at the top of each rockwool cube. Make sure the seeds have been “activated” by wetting them with some water to help them germinate. Ensure that the rockwool cubes are sitting in about 1cm of water as this will help them stay hydrated. To maximise success with germination, you can use a clear glass or plastic cup/bowl/container to create a warm and humid greenhouse effect which can speed up the progress of your seeds sprouting.

USING ROCKWOOL TO PRODUCE ROOT CUTTINGS

Cuttings can be rooted in rockwool. Prepare by soaking the rockwool cube in water, then simply cut the propagules from the parent plant (usually just below a “node” on the plant stem), and then trim some of the unecessary leaves back. Dip the cutting in rooting hormone (optional) and embed the cutting slightly in the hole at the top of the rockwool cube. Keep the cutting in bright indirect light

DIFFERENCES BETWEEN STONE WOOL AND OTHER GROWING MEDIA

The main difference between stone wool, coco coir, peat and soil growing media is that stone wool is mineral-based, not carbon-containing organic matter. It is made of natural stone, not coconut husks, bog-sourced peat moss or the composted wood byproducts found in most potting soils.

During manufacturing of stone wool, it is heated to such extreme temperatures of about 3,000°F/ 1500°C. This makes it hygienic, clean growing media free of pathogens. It is also fully compatible with hydroponic and automated growing systems, as well as automated irrigation technologies that rely on precise control unlike other substrate medium.

PRECAUTIONS WHEN USING ROCK WOOL

1. It is recommended that rock wool is steamed or at least treated with boiling water before replanting to help prevent any carry over of root disease pathogens.

2. A thorough leaching with clean water can helps remove any excess salts from the previous crop planted.

3. Chemical disinfectants can be used to treat rock wool before use. However, care needs to be taken to completely rinse these chemicals from the material before replanting and steam or hot water can be used which is a much safer option.

4. After use of rock wool material, it should be disposed off. Often, growers simply dump them causing environmental pollution. However, this materials can be shred and re use as a growing mixes, or incorporate it into outdoor soils and gardens as a soil conditioner.