Seed refers to the fertilized, matured ovule that contains an embryonic plant, stored material and a protective coat or coats. A seed is a mature ovule that comprises an embryo or a miniature undeveloped plant and food reserves, all enclosed within a protective seed coat.

TYPES OF SEEDS

There are two types of seeds: Monocotyledonous seeds. Dicotyledonous seeds.

STRUCTURE OF A MONOCOTYLEDONOUS SEED

A Monocotyledonous seed has only one cotyledon. There is only one outer layering of the seed coat. Examples of such seeds include seeds of cereals, grasses etc. Such seeds have the following parts:

SEED COAT : The seed coat is membranous and fused with the fruit wall, called Hull.

ENDOSPERM : The endosperm is bulky and stores food.

ALEURON LAYER : The outer covering of endosperm separates the embryo by a proteinous layer called aleurone layer.

EMBRYO : The embryo is small and situated in a groove at one end of the endosperm.

SCUTELLUM : This is a large and shield-shaped cotyledon.

EMBRYONAL AXIS : Plumule and radicle terminate at an end called embryonal axis.

COLEOPTILE AND COLEORHIZA : The plumule and radicle are enclosed in sheaths. They are the coleoptile and coleorhiza respectively.

STRUCTURE OF A DICOTYLEDONOUS SEED

Dicotyledonous seed has two cotyledons. It has the following parts:

SEED COAT : Which is the outermost covering of a seed and it has two layers, the outer testa and the inner tegmen.

HILUM : The hilum is a scar on the seed coat through which the developing seed get attached to the fruit.

MICROPYLE : It is a small pore present above the hilum.

EMBRYO : It consists of an embryonal axis and two cotyledons.

COTYLEDONS : These are often fleshy and full of reserve food materials . They are also called seedleafs.

RADICLE AND PLUMULE : They are present at the two ends of the embryonal axis.

ENDOSPERM : In some seeds such as castor, the endosperm formed as a result of double fertilisation. The endosperm is a food storing tissue. In plants such as bean and pea, the endosperm is not present in the matured seed. They are known as non-endospermous.

CLASSIFICATION OF SEEDS

There are four main classes of seeds:

i. Breeder : made from a nucleus seed.

ii. Foundation :made from breeder seeds.

iii. Registered :progeny of a foundation seed that maintains its purity according to specified standards.

iv. Certified : progeny of foundation seeds made by registered seed growers.

SEED QUALITY

Seed quality is a collection of seed properties which are considered to be of importance for the value of the seed for sowing purposes.

COMPONENTS OF SEEDS

i. Genetic purity

ii. Analytical purity

iii. Germination capacity

iv. Size and uniformity

v. Seed health

vi. Seed moisture content

vii. Specie purity

viii. free from weed seed

ix. Vigor

x. Density (specific gravity) etc

SEED PRODUCTION AND PROCESSING

SEED PROCESSING / SEED CONDITIONING: Processing of seed provide a storable product. Seed processing needs to be optimal inorder to have high quality seed production. For the quality of seed not to be reduced, a good processing technique is required.

Seed processing therefore can be defined as all the steps necessary for the preparation of harvested seeds for marketing, handling, drying, shelling, preconditioning, cleaning, size grading, treating and packaging.

Seed processing conditioning start with harvesting of the seed from the field. Seedlot from the field often contain high moisture content. It might be mixed with weed seeds, inert materials, trash, small seeds and damaged seeds etc and processing concentrate the desired crop seeds by removing all these extrement matters.

It is important to store seeds from one season to the next. The way seeds are Harvested, processed and storaged affect the longevity and vigor of the seeds.

COMPONENTS OF SEED PROCESSING

The components of seed processing are the steps involved in the processing of the seeds. The steps include:

a. Drying b. Cleaning. c. Blending d. Grading e. Sizing f. Treatment g. Packaging

HARVESTING: Some seeds within plant fruits are enclosed within a protective covering called endocarp. Some like maize are enclosed in the leaf sheath of bract. Cochorus seeds are enclosed in a hard capsule, some are located within the fruits and legumes seeds enclosed in pods etc.

Seeds are usually allowed to mature as long as possible on the plant. Seeds to be used as propagules must not be extracted from diseased tree or fruits or unripe fruits. Different plants have their own optimum time for the seeds to be collected. But certain factors may bring about early collection of the seeds before the optimum time. Such factors include climate, animals feeding on the seeds such as birds and insects, and other mammals etc. Most seeds are collected when the fruits, pods etc ripen.

SEED MOISTURE CONTENT: The moisture content of dry seed may be determined by using moisture content determining machine. The seed moisture content can also be determined manually. Manual determination of seed moisture content can be carried out by grinding a sample from the seedlot. The seed should be put in a container and covered up. The container should then be put in an oven after weighing at a temperature of 135 oC for 2 hours. After the time limit, the container should be removed from the oven and cool in a dessicator for 30 minutes. The heated seed should be reweighed again. The second seed weight should be subtracted from the first seed weight before heating and multiply by 100 to give the moisture content of the seed expressed in percentage.

SEED. First weight. _ Ovendried *100

moisture = before ovendrying. Weight

content

EFFECT OF HIGH MOISTURE CONTENT IN SEEDS

1. Moisture increases seed respiration rate.

2. The respiration rate caused by high moisture content in seeds increases the seed temperature in large scale storage. This kills the seed

3. It affect the longevity and storage lenght of the seeds

4. High seed moisture content encourages growth of mold

SEED DRYING: For some seeds to germinate, their moisture content must be reduced to the nearest minimum. Low moisture content is a prerequisite for long storage. Seeds lose viability and vigor during storage simply because the moisture content is high (>18%)

Atimes seeds are threshed immediately after harvesting or dried before threshing. For example, maize are atimes dried with the sheath before threshing. While most legumes are threshed before drying and vise versa. Seed drying involved spreading the seeds out on a flat surface covered with polythene sheets or tarpaulin in an open air (air drying). Otherwise, the seeds will grow mold, or decay. The heat from the decay will increase the temperature within the seed and damage it. Therefore, the seeds are stirred to create even spread of air for drying. As the plant materials such as the sheath, pods, capsules etc and the seeds within them dry up, the pods and capsules will split open easily and shed seeds, while sheath of maize becomes easy to remove with maize grains still held to cobs.

Harvested materials should be stored in a dry, well ventilated room with low humidity. Also, farmers should be watchful of storage pests like weevils and other storage pests that gain entry into the storage room. After harvesting and atimes drying, threshing and shelling follows.

THRESHING AND SHELLING: Timely shelling is determined by the moisture content of the seed which is important in future germination capacity of the seed lot. It is best done outdoor on a dry day. Threshing is done by hand or use of machines. The threshing process involves the application of a mechanical force using controlled pressure and a shearing motion.

Example of crops that are shelled include maize, soybeans, cowpea and groundnut etc.

METHODS OF THRESHING

Different crops have different method of threshing their seeds. The following methods are used:

a. PODS: crops like cowpea, soybeans, lema bean etc can be threshed by putting the pods in a large sack and the mouth tied. The sack is then placed on a dry flat ground and it is matched upon by foot. The sack is turned to the other side and matched upon again. Also, a wooden stick or mortar and pestle can be used for threshing the pods in the sack but care must be taken not to apply too mush force as this may damage or break the seeds.

b. MAIZE COBS: Maize cobs can be threshed using a wooden stick or mortar and paste like that used for pods. The cobs are also put in sack for threshing. Also, hand can be used to separate the seeds from the cobs. This is a much safer method as less or no damage will be done to the seeds unlike using sticks or mortar and pestle.

c. TASSLES: crops like rice, guinea corn, wheat, etc produce grains in their tassels. Such grains can be threshed by beating the tassels on a dry clean ground or wooden plank placed on the clean ground.

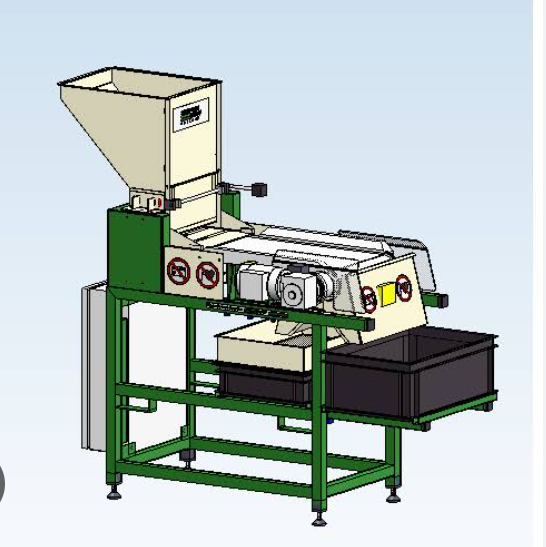

Modern technology has now brought about development of threshing machines both for small scale production of seeds and large scale production. Instead of the above local methods, thresher can easily seperate seeds without causing damage to the grains and this increases the market value of the grains.

SEED CLEANING: This is the art of removing inert materials, weed seeds, stones etc and treating seed so that it has an upgraded market value. Majority of crop seeds can be cleaned using homemade screens and winnowing. Also, sophisticated machines are now available for cleaning of seeds but expensive.

CLEANING DEVICES

A. SEPARATOR: This device operate with a fan and screen principle. The device operates by removing or get rid of materials that are tight in the seed. It can be used to clean Amaranthus, celosia and some vegetable seeds. Without the fan and screen, winnowing( blowing free) can be done. There are different types of separators: colour separator, fraction separator, disk separator, spiral separator and air separator etc.

WINNOWING: This is a process of removing chaff of the blow free of chaff by an air current. This is usually carried out on grain crops, okro, cochorus etc. whose chaffs are light. After the seeds are removed from the splitter capsules, they are winnowed. Also, the chaff in amaranthus and celosia seeds can be winnowed.

Winnowing can be done locally by placing the seeds in a basket and tossing the seeds in the air in the wind direction. The chaff will be blown away by the wind. Or using two bowls in which the seeds are poured from one bowl into the second bowl in the wind direction or blow air to it to remove the chaff. Also, machines are designed to carry out Winnowing.

Other cleaning devices include air screen cleaner which removes light materials from the seed lots such as chaff, dust, and light weighed seeds with the use of air blast or aspirators.

SIZING: Sizing of seeds is carried out so as to remove large or smaller seeds from average sized seeds. Sizing can be carried out by hand picking. Sizing of seed is better achieved on grain crops, vegetables such as okro, cochorus, etc.

GRADING: Grading is usually done to achieve seed uniformity. Grading is the removal of cracked, damaged, defective, infected, shrivelled seeds from the seedlot. For example, okro seeds darker in colour than other seeds in seedlot shows that the seeds are infected. Therefore should be separated to increase the market value. Grading can be done by hand picking of bad seeds and sight.

BLENDING: A seed mixture or seed blend is an intentionally produced, randomly mixed set of two or more kinds of crop seed.

The difference between seed mixture and seed blending is that mixture consists of different species of crop seed and may contain more than one variety of a species. A blend consists of one species with several varieties. That is combining two or more varieties of the same species. Selecting a blend is better than selecting a single variety since each variety has strengths and weaknesses.

Seed blending is usually carried out to separate the different varieties of species to create a pure variety. For example ; Butterhead Lettuce and

Crisphead Lettuce seeds.

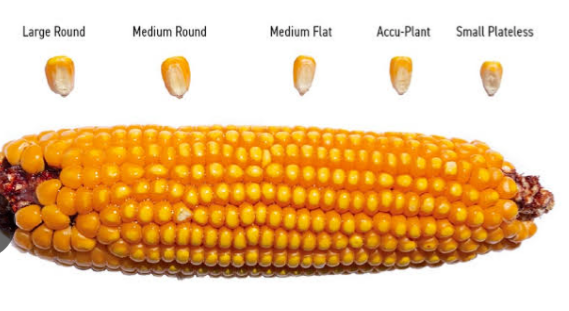

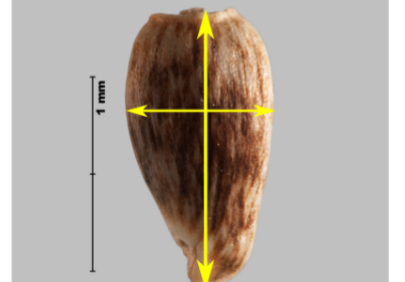

SIZING: . The most important seed components along the processing line assembled for cleaning and grading the final product is the seed size and weight. Seed size is an important seed identification feature along with seed shape and seed texture. The first physical seed trait has three components necessary for cleaning and grading: the seed length, width and thickness

SEED SIZE : the size range of mature and normal seeds of a species.

SEED LENGTH : the maximum seed length of a seed under measurement is usually the longest axis of the seed.

SEED WIDTH : the maximum seed width of a seed under measurement is usually the second longest axis, perpendicular or nearly so to the length axis.

SEED THICKNESS : the maximum seed thickness under measurement is usually the third longest axis, .

Seed size measurement is based on the size variation of mature seeds of a species. The standard for seed size measurement is based on a minimum of 10 seeds. However, when the population is highly variable, the measurement may be increased to 20 seeds. Seed size can be measured by two main methods:

a. image measurement

b. manual measurement

All measurements are expressed in either millimeter (mm) or centimeters (cm) to one or two decimal places. Use of an appropriate level of magnification, for example, 10x-40x during the measurement is recommended.

SEED TREATMENT: Seed treatments, in broad terms, are the application of biological, physical and chemical agents and techniques to seed that provide protection to seeds and plants and improve the establishment of healthy crops. The treatment substances exist as synthetic and organic seed treatments.

Different methods of seed treatment include:

a. FUNGICIDAL AND INSECTICIDAL DRESSING : fungicides are used to controls fungal diseases like smuts, rots, or seedling blights. While the insecticide is used to tackle insect infestation.

b. HARDENING : This involve soaking the seed in a specific solution to make seedlings more resilient to cold and droughts. It also speeds up germination, which starts after the solution absorption

c. FORTIFICATION : This involves fortifying the seeds with nutrients so as to boost seedlings’ vigor and make them more tolerant of unfavorable soil environments

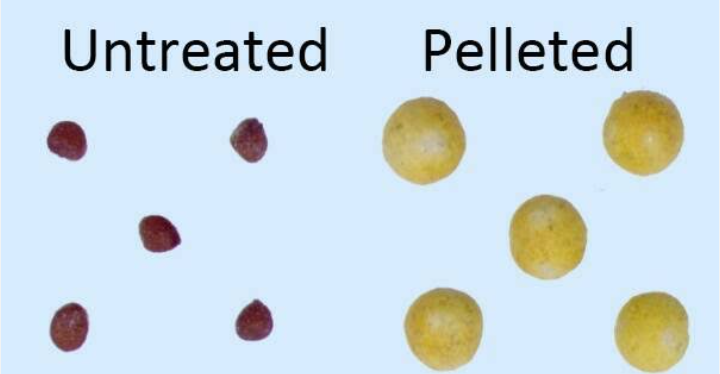

d. PELLETING : This involves coating the planting material with inert substances that increase its shape, size, and weight. The inert substances like lime, chalk or talcum stick are coated to the seed with adhesives.

e. INFUSION : This involves the use of substances that slowly penetrate the seed with the help of organic solvents, for example, acetone or dichloromethane. The benefit of this method is that it does not require long-time drying.

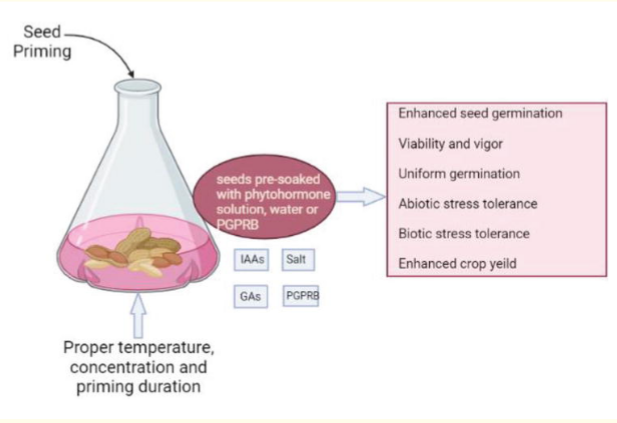

f. OSMOTIC PRIMING : This is a relatively expensive treatment method. This mostly used on legume seeds with big embryos and high protein content. In the case of osmopriming, water absorption is slowed down by osmotic agents. Typically used osmotic solutions are polyethylene glycol or salt solutions like KNO3, NaCl, or K3PO4.

G. FLUID DRILLING : This method is applied to germinated planting material and aims to protect it while sowing

SEED DRESSING : This is the most common method of seed treatment. The seed is dressed with either a dry formulation or wet treated with a slurry or liquid formulation. Dressings can be applied at both farm and industries

SEED STORAGE: The major purpose of seed storage is to maintain seeds in a viable state, so that they can germinate and produce healthy, vigorous plants. For agricultural purposes seed may be stored for several years.

To conserve seeds for preservation of genetic diversity, the seeds are stored in seed banks, where facilities are designed to maintain seed viability for many years up to hundreds of years.

Certain conditions should be maintained to keep the seed viable and in good vigor. Such conditions include: Adequate temperature and humidity, sealable storage containers, and storage atmosphere like oxygen that causes deterioration of the seeds. While gases like nitrogen or carbon dioxide or storage under vacuum may improve seed longevity.

PURPOSE FOR SEED STORAGE

The purpose of seed storage is to:

a. Maintain the seed in good physical and physiological condition from the time they are harvested until the time they are planted.

b. Seed suppliers do not always market all the seed they produce during the planting season. In many cases, the unsold seed are “carried over” in storage for marketing during the second planting season. Carryover storage of some seeds are problematic because some kinds, varieties and lots of seed do not carryover very well.

c. To eliminate the need to produce seed every season.

d. Some kinds of seeds are stored for extended periods to improve the percentage and rapidity of germination by providing enough time for a “natural” release from dormancy. That is to maintain a satisfactory capacity for germination and emergence.

e. To conserve food value and viability.

FACTORS AFFECTING SEED LONGEVITY IN STORAGE

i. Moisture content

ii. Relative humidity and temperature during storage

iii. Kind (or) variety of seed

iv. Initial seed quality

v. Provenance

vi. The activity of storage organisms (pest) on the stored seeds

vii. Seed coat. Seeds with harder seed coats tend to store longer than those with thin coats.