Soil fertility evaluation is the process by which nutritional problems are diagnosed and fertilizer recommendation are made. It is simply the measurement or assessment of the fertility status of a soil. There are several methods used to evaluate soil fertility. Such methods include: soil testing, plant analysis, missing element technique, field trials, greenhouse studies, microbiology assay, rapid tissue analysis and visual observation or recognisance survey.

Soil analysis is important in agriculture and the environment. It is essential for assessing, monitoring and giving information about the chemical and physical conditions of the soil, indicating the need for fertilization, liming and conservation practices. It is carried out in the laboratory using chemical methods called traditional wet analysis.

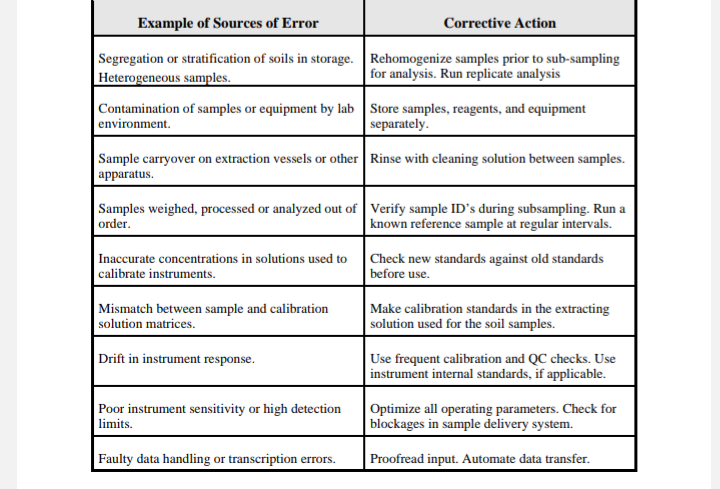

During soil analyses several errors do occur. These errors are due to sampling, products, methods used, humans, and others etc. These makes analytical result inaccurate and unreliable, thus, affecting farming practices. This gives reason why quality control and assurance are important factors in estimation of analytical results sourced from the laboratory.

The term quality implies keeping to a standard procedure to achieve a significant or error free result. In order to maintain quality, quality control and assurance procedures must be involved.

WHAT IS QUALITY CONTROL?

Quality assurance (QA) focuses on the process of the analysis with the purpose of preventing and/or limiting the occurrence of errors in the measurement. A quality assurance program is an integral part of quality assurance necessary for all laboratories to document analytical uncertainty and to promote confidence in analytical result. It is divided into two parts: quality control and quality assessment.

Quality control (QC) is a set of activities or techniques aiming to ensure that all quality requirements are being met. It comprises of those laboratory practices which are undertaken specifically to achieve accurate and reliable analytical result.

Quality assessment include those processes undertaken to monitor and document the effectiveness of quality control program. And it is used to determine if an analytical process is meeting quality assurance guidelines.

Quality control is an essential part of good laboratory practices. During routine analysis, errors may gradually appear due to contamination, changes in reagent quality, environmental differences, operation error, instrument calibration or failure.

TYPES OF QUALITY CONTROL

There are two types of quality control. They include: internal and external quality control

1. INTERNAL QUALITY CONTROL :These are set of procedure undertaken by laboratories to monitor operations within the laboratory and end results of analytical procedures.

2. EXTERNAL QUALITY CONTROL: it is also called proficiency testing or inter-laboratory comparison. It involves a periodic assessment of the performance of individual and groups of laboratories. The assessment is done by independent testing body such as Global Soil Information System (GloSIS), Global Soil Laboratory Network (GLOSOLAN), and global soil data exchange, The international network of soil information institution (INSSI),The international network of black soil etc . They aim towards providing a platform for active engagement in sustainable soil management and soil protection at all scales. Their mandate is carried out through distribution of materials for unsupervised analysis by participants. Proficiency testing is used as a tool to assess and enhance standards of the analysis, and assist in the standardisation of soil analytical methods across laboratories leading to more reliable and interoperable soil data. Laboratories can use the results obtained in the Proficiency Testing to identify areas where improvements may need to occur.

QUALITY CONTROL PARAMETERS

Some quality control parameters include: calibration function characteristics, limits of detection, limits of quantification, quality control standards, duplicate analysis, spike recoveries and certified reference materials analysis

HOW TO ENSURE QUALITY AND ASSURANCE IN LABORATORY PROCEDURES

Repeated measurement of an air dried soil sample should provide consistent result when analysed over time for most routine chemical procedures. The deviation of an observed value from its absolute true value result from either system or random errors. Once identified, system errors are more easily corrected than those which occurs at random.

Three precautions are essential for laboratory quality control and should be routinely included among test samples. These includes: the use of blanks, repeats and internal references.

BLANKS: These are reaction vessels that are subjected to identical procedure as the sample in a given batch which have no added test material. Blank are simply referred to as a solution that contains no analyte in analytical process. The analyte is the substance that the laboratory scientist wants to quantify. Blanks are commonly used to calibrate instruments such as calorimeters and also used to set the baseline in spectrophotometric experiments. They are often composed of the buffer in which an analyte is dissolved. It is important to subtract the absorbance of the blank when taking spectrophotometric measurements. This allows the scientist to accurately quantify the amount of analyte which is present in a sample. It also allows correction for any background contamination introduced from reagents, filter paper or other systemic sources of error.

REPEATS: At least, one in ten samples selected from the test materials and placed at random within the batch should be analysed in duplicate.

The choice of 1 to 10 is a suggested compromise between the ideal of analyzing all samples in duplicate, considering the time. Analytical result from given pairs of duplicate repeats should closely resemble one another. In general, repeat values should fall within +or – 2.5 to 5.0%. It then means, depending on the analysis in question, any greater discrepancy must be investigated in repeated values if not consistent, the entire batch should be re-analysed.

INTERNAL REFERENCES: Reference sample is a unit of a quantity with which the amounts of other quantities of the same kind are compared. The accuracy of analytical result can be documented by analyzing reference sample of known content. A reference sample is homogenized sample as similar as possible to the routine sample being tested. Internal reference sample are necessary for any type of test material and analysis practiced within the laboratory. The internal sample should not be the same as the homogeneous material routinely used in the testing of new method and analytical techniques. The most useful reference samples are those that have become available through proficiency testing program. In this programs, samples of homogenized soils are sent to all corperating laboratories for analysis using specified methods. Analytical result for the internal reference may be plotted on a quality control chart, to monitor the performance of the analysis over time.

COMPONENTS OF A QUALITY CONTROL PROGRAM

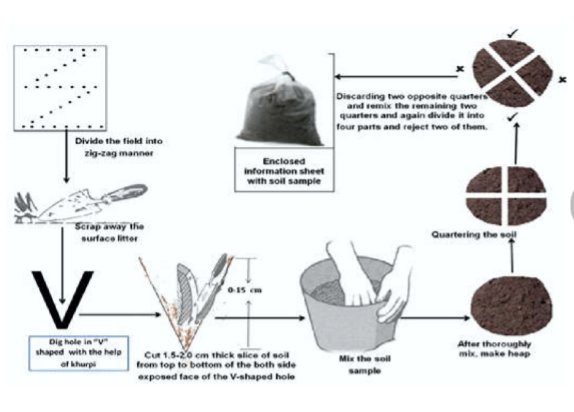

A good quality control program include documentation, training and implementation of good laboratory practices and procedure. Quality control program start from sample collection from the field to when all laboratory operations are carried out. Improper sampling may affect the final result of the analysis. There is need for complete listing of standard operation procedure.

Quality control technique also involve stating or writing the summary of known source of error in laboratory operation which will assist or benefit new employee.

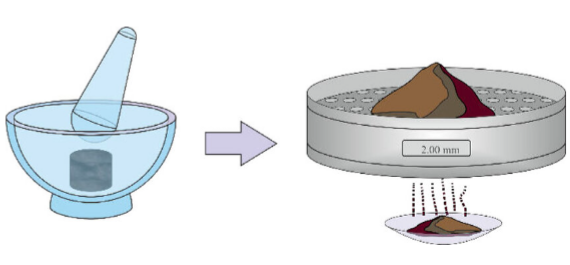

For sample preparation, the convenience of handling and providing a homogeneous mix for sub – sampling soil samples are usually air dried and pulverised. Sub- samples of the dry, pulverised soil are either weighed or measured by volume. Galvanised containers, cast iron mortars, rubber stoppers, brass screens and a variety of other tools can contribute to contamination with iron, zinc and other micronutrients and should not be used.

SAMPLE HANDLING: Before analysis, sample handling can affect soil test results. Drying can result in increased release of exchangeable Potassium (K) in many soils and fixation in others. The fixation tends to occur in recently fertilize soils with higher test levels. The extent of reversion on rewetting varies among soils and is seldom if ever complete. Increased temperature can also increase exchangeable K level. The K released on drying and the reversion on rewetting can be controlled with organic additives. But this procedure has not being evaluated in practical soil test.

DRYING: Both drying and method of drying can affect the tests for mineralizable nitrogen, phosphorus and micronutrients, but the correlations between the test results and uptake of nutrients by plants have not been shown to be significantly affected by drying

Because of the difficulties of analysing moist samples and because most correlations and calibrations studies have been done on air dry soils, the wet soil analysis method has not been adopted wisely. Traditionally, drying of soils have been the convenient state required before analyzing the soil chemically. Materials used in drying include paper bags, cardboard boxes or aluminium trays placed on a denying rack or cabinet which may be equipped with exhaust fans to expedite air movement and moisture loss.

CRUSHING AND SEIVING: Crushing and sieving are done to reduce size of the cluds and separate particles greater than 2mm and those less than 2mm. For micronutrient analysis, it is essential that all surfaces coming into contact with the soil must be from stainless steel, plastic or wooden equipment.

EXTRACTION: After the sample have been weighed or measured, those not requiring digestion must be manipulated in order to get the element of interest into solution. Extractants are developed for this purpose. Sometimes, more details are over looked when extractions are done in the laboratory. That is processing large numbers of samples under time pressure. This include factors such as the means of shaking, rate of reciprocating, type of extraction vessels, extraction time and laboratory temperature. Although, these factors are sometimes not given a lot of attention, they can have a significant impact on the test result.

SHAKING AND STIRRING: Shaking and stirring are done mechanically when extracting solutions. They are shaked at exact rate, lower extractable nutrient will be obtained. EXTRACTION TIME: Each test has a recommended extraction (shake and reflex) time that should be strictly followed. A number of studies have shown that for some tests, an extraction time other than the recommended time can have significant effect on the amount of nutrients extracted. For example, with the DTPA test, it has been found that shaking for 15 minutes beyond the 2 hours recommended shaking time can result in a significant increase in the amount of micronutrients extracted from some soil.

LABORATORY TEMPERATURE : The temperature of the laboratory is an often overlooked factor in laboratory analysis. One of the areas where temperature has impact is on the pH measurement. If pH reference buffers are at the same temperature as the samples or if the measurement are not temperature compensated, the error can be as much as 0.05pH unit for every oC change in temperature. A study reported that the temperature of extraction was an important factor in sodium bicarbonate extractable P. The extractable P increases with temperature over the range of 14 to 33oC. Therefore, it was recommended that laboratory temperatures be maintained between 24 to 27 oC for routine extraction

SOURCES OF ERROR IN SOIL TESTING LABORATORY

Most of the errors stated in the above table are peculiar to specific apparatus or processes in the laboratory which the field employee have to take note of.

The error log (table) do promote continuity within a group or succession of technicians (operator) as well as more consistent operations overtime for any individual technician.

In conclusion, quality assessment and quality control is achieved through systematic documentation of accurate and precise analytical procedures.